Gas-Solid Spouted Cylinder Bed#

This example is an extension of the Gas-Solid Spouted Bed for a cylindrical geometry.

Features#

Solvers:

lethe-particlesandlethe-fluid-particlesThree-dimensional problem

Simulates a solid-gas cylinder-shaped spouted bed

Files Used in this Example#

Both files mentioned below are located in the example’s folder (examples/unresolved-cfd-dem/gas-solid-spouted-cylinder-bed).

Parameter file for particle generation and packing:

packing-particles.prmParameter file for CFD-DEM simulation of the spouted bed:

gas-solid-spouted-cylinder-bed.prm

Description of the Case#

This example simulates the spouting of spherical particles in a cylinder. As noted in the example of Gas-Solid Spouted Bed, we use lethe-particles to fill the bed with particles, and lethe-fluid-particles as the unresolved CFD-DEM solver.

DEM Parameter File#

Here, we will focus only on the parts that have been modified compared to the Gas-Solid Spouted Bed example. It is also strongly recommended to visit the DEM parameters for a detailed description on the concepts and physical meanings of the DEM parameters.

Mesh#

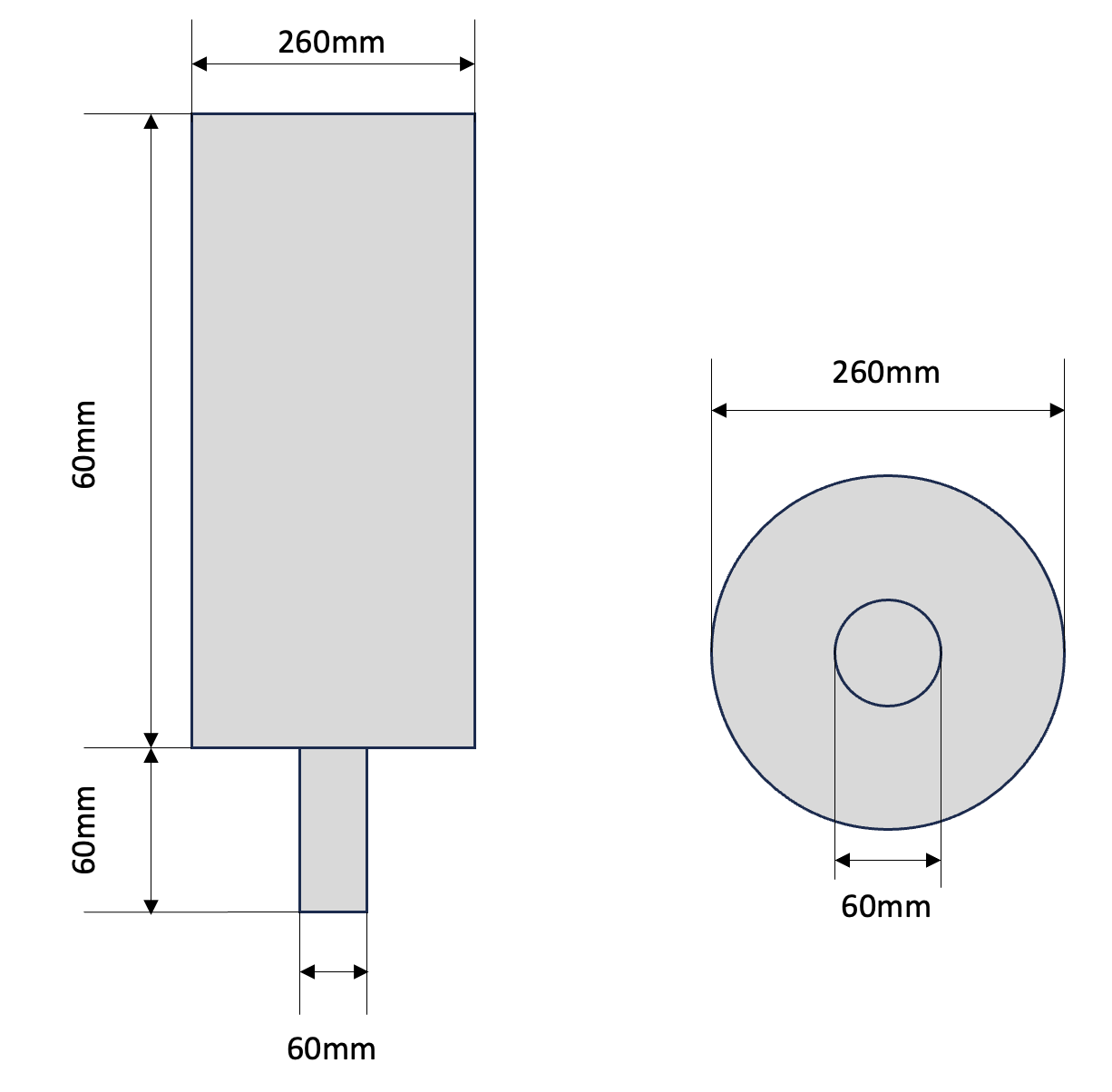

In this example, we are simulating a cylinder shaped spouted bed. We introduce the flow through a cylinder of smaller radius that constitutes the inlet of the bed. A schematic image is shown below;

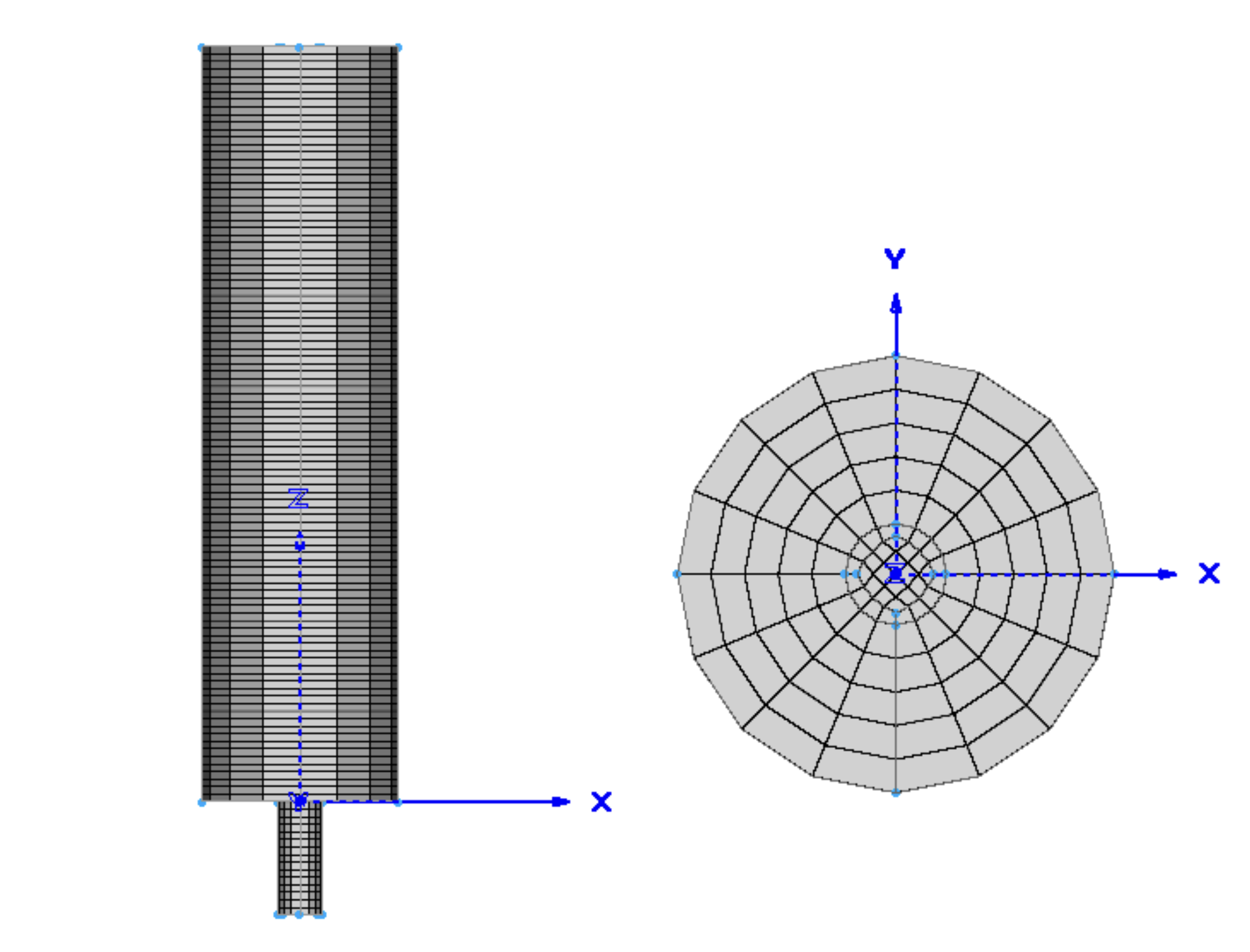

The geometry of the bed was created using Pointwise. An overview of the mesh is:

In unresolved CFD-DEM, the averaging volume used to calculate the void fraction needs to be large enough to contain several particles (>10). Since the averaging volume used in the quadrature-centred method is generally related to the cell volume, this introduces a limitation on the cell size. In general, the averaging volume, which in this case is controlled by the cell size, should be approximately three times larger than the diameter of the particles in order to get stable calculation.

subsection mesh

set type = gmsh

set file name = ./mesh/cylinder-spouted-bed.msh

set expand particle-wall contact search = true

end

where the file name includes the path to the mesh file. Here, we activate expand particle-wall contact search, which is only used in geometries with concave boundary such as cylinder and sphere. For more details, please refer to Mesh Parameters Guide.

Lagrangian Physical Properties#

In this simulation, we use 100,000 particles with a 5 mm diameter. The rest of the particle properties are relatively standard.

subsection lagrangian physical properties

set number of particle types = 1

subsection particle type 0

set size distribution type = uniform

set diameter = 0.005

set number = 100000

set density particles = 100

set young modulus particles = 1e7

set poisson ratio particles = 0.25

set restitution coefficient particles = 0.97

set friction coefficient particles = 0.4

set rolling friction particles = 0.3

end

set young modulus wall = 1e7

set poisson ratio wall = 0.25

set restitution coefficient wall = 0.33

set friction coefficient wall = 0.2

set rolling friction wall = 0.3

end

Insertion Info#

The insertion info subsection manages the insertion of particles. The insertion box parameter is set so that it can fit within the cylinder.

subsection insertion info

set insertion method = volume

set inserted number of particles at each time step = 100000

set insertion frequency = 2000

set insertion box points coordinates = -0.075, -0.075, 0, 0.075, 0.075, 0.7

set insertion distance threshold = 1.05

set insertion maximum offset = 0.3

set insertion prn seed = 19

end

Floating Walls#

We place a floating wall at the bottom of the cylinder, which is at \(z = 0\), to ensure that the particles remain within the cylinder during the loading step.

subsection floating walls

set number of floating walls = 1

subsection wall 0

set point on wall = 0., 0., 0.

set normal vector = 0., 0., 1.

set start time = 0

set end time = 999

end

end

Running the DEM Simulation#

Assuming that the lethe-particles executable is within your path, the simulation can be launched in parallel as follows:

Note

Running the packing should take approximately 10 minutes on 8 cores.

After the particles have been packed inside the bed, we can move on to the fluid-particles simulation.

CFD-DEM Parameter File#

The CFD-DEM simulation is carried out using the packed bed previously generated. Here we will focus on the modified section as well. We recommend visiting the Unresolved CFD-DEM Parameters Guide for a detailed description.

Simulation Control#

The simulation is run for 5 seconds with a time step of 0.001 seconds. The time scheme and setting for output is shown as follows:

subsection simulation control

set method = bdf2

set number mesh adapt = 0

set output frequency = 50

set time end = 5

set time step = 0.001

end

Boundary Conditions#

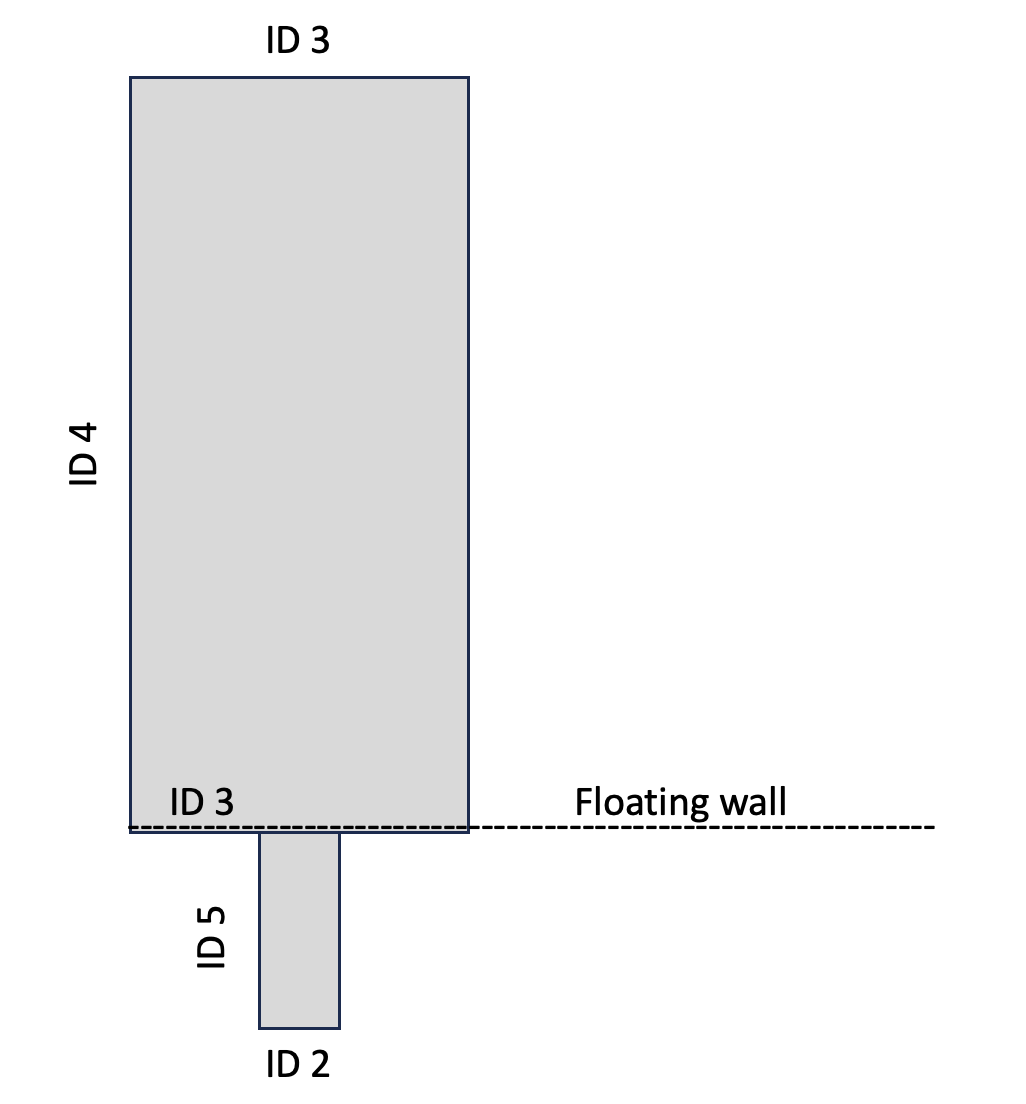

Regarding the boundary conditions, we apply slip boundary condition to the wall, a uniform Dirichlet boundary condition at the bottom of the small channel, and outlet to the top of the cylinder. The following schematic figure describes the ID of each boundary and the positon of the floating wall.

We set the inlet velocity to 2.5 m/s, and the background velocity to 0.5 m/s on the bottom of the cylinder as in the previous spouted bed example. The value of beta on the outlet boundary was set to 100, which is relatively high, to stabilize the simulation and prevent backflow.

subsection boundary conditions

set time dependent = false

set number = 5

subsection bc 0 #outlet

set id = 3

set type = outlet

set beta = 100

end

subsection bc 1 #inlet

set id = 2

set type = function

subsection u

set Function expression = 0

end

subsection v

set Function expression = 0

end

subsection w

set Function expression = 2.5

end

end

subsection bc 2 #wall

set id = 6

set type = slip

end

subsection bc 3 #channel_wall

set id = 5

set type = slip

end

subsection bc 4 #bed_wall_bottom

set id = 4

set type = function

subsection u

set Function expression = 0

end

subsection v

set Function expression = 0

end

subsection w

see Function expression = 0.5

end

end

end

CFD-DEM#

Here, we enable grad-div stabilization, and take the time derivative of the void fraction into account.

subsection cfd-dem

set grad div = true

set void fraction time derivative = true

set drag force = true

set buoyancy force = true

set shear force = true

set pressure force = true

set saffman lift force = false

set drag model = rong

set post processing = true

set coupling frequency = 100

set implicit stabilization = true

set grad-div length scale = 0.26

set vans model = modelA

end

We set the grad-div length stabilization parameter to 0.26, which is the diameter of the geometry. This parameter should be the same length as the characteristic length of the flow. For more detail, please refer to CFD-DEM parameters. Also, the additional sections for the CFD-DEM simulations is the void fraction subsection. This subsections is described in detail in the Void Fraction.

Running the CFD-DEM Simulation#

The simulation is run using the lethe-fluid-particles application. Assuming that the lethe-fluid-particles executable is within your path, the simulation can be launched as per the following command:

Note

Running the packing should take approximately 5 days on 8 cores.

Results#

We briefly discuss the results that can be obtained from this example here.

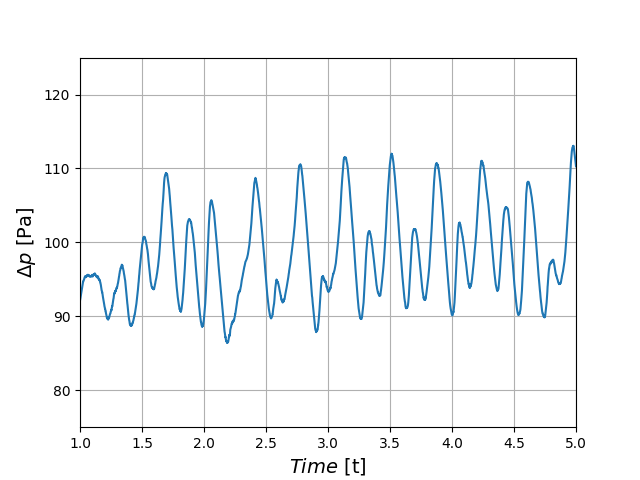

Total Pressure Drop#

The following plot illustrates the variation of pressure drop from 1 second to 5 seconds. We can see the pressure oscillation which is caused by the bubbly state of the spouted bed.

Visualization#

In the following animation, the bubbly flow can be observed on the right side. the color of the particles represents their IDs, allowing for the visualization of the mixing. On the left side, we show the fluid velocity field.