Flow around NACA0012 at Low Reynolds Number#

Features#

Solver:

lethe-fluid(with Q1-Q1)Transient problem

Boundary Layer Mesh - Transfinite Mesh

Spectral analysis - Fourier transform

Files Used in This Example#

All files mentioned below are located in the example’s folder (examples/incompressible-flow/2d-naca0012-low-reynolds).

Geometry file:

c_type_mesh.geoParameter file for the base case (\(Re=1000\)):

naca.prmPostprocessing Python script:

postprocessing.py

Description of the Case#

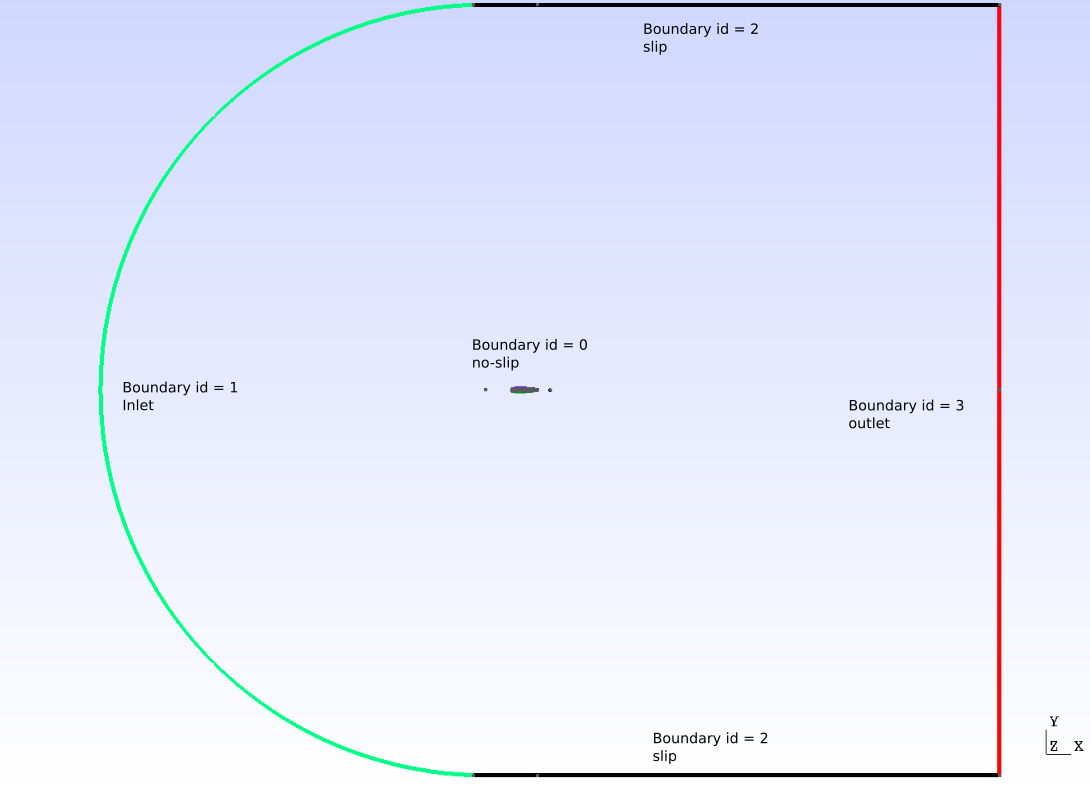

In this example, a two-dimensional flow around a NACA airfoil is studied. According to Wikipedia, the NACA airfoils are airfoil shapes for aircraft wings developed by the National Advisory Committee for Aeronautics (NACA). The NACA is the ancestor of the well-known NASA. The airfoils, simply referred to as NACAs afterwards, can be described by a set of four digits for the simpler airfoils, allowing the generation of a lot of different profiles. Since we deal with a symmetrical NACA we will only consider the last two digits, which describe the maximum thickness of the airfoil in percentage of the chord. The first two digits, describing the maximum camber and its position, are set to zero. The problem under study is presented in the figure below, which details the boundary conditions chosen and gives an idea of the size of the computational domain.

These airfoils, though created almost 100 years ago, are still very popular in aerodynamic fields where they often serve as a base choice, which is then modified to fit the constructor’s constraints. The literature on numerical simulations of NACAs with high Reynolds numbers (\(Re>10^6\)) is abundant. However, recent technological developments in the field of Micro Air Vehicles (MAVs) created a need for low Reynolds simulations (\(Re<10^4\)) since these vehicles operate at Reynolds numbers much smaller than usual aircraft. In this example, a 2D simulation around a NACA0012 at \(Re=1000\) will be performed in order to retrieve significant quantities such as drag, lift, and pressure coefficients, respectively denoted by \(C_D\), \(C_L\) and \(C_p\). Elements of order 1 will be used for pressure and velocity. A spectral analysis will then be performed to analyze the vortex shedding frequency.

Parameter File#

Simulation Control#

The problem is transient. An adaptative time step is used to ensure that the CFL \(<10\) condition is obtained. This boundary for the CFL number was chosen to get relevant results while having reasonable simulation times. The reader is referred to the Lid-Driven Cavity Flow example for a better understanding of the time step adaptation to keep the CFL below a certain threshold. A second-order backward differentiation (BDF2) scheme was chosen.

subsection simulation control

set method = bdf2

set output name = naca-output

set output path = ./output/

set output frequency = 50

set adapt time step to respect CFL = true

set max cfl = 10

set time end = 40

set time step = 0.01

end

Physical Properties#

In this problem, the Reynolds number is defined as:

where \(C\) is the chord length of the airfoil, \(u_{\infty}\) is the magnitude of the inlet velocity (free-stream velocity) and \(\nu\) the kinematic viscosity. \(C\) and \(u_{\infty}\) are taken equal to 1. Then, in order to get \(Re = 1000\), one must have \(\nu = 0.001\).

subsection physical properties

subsection fluid 0

set kinematic viscosity = 0.001

end

end

Forces#

The forces are computed in order to obtain the drag and lift coefficients later on:

subsection forces

set verbosity = verbose

set calculate force = true

set calculate torque = false

set force name = force

end

Mesh#

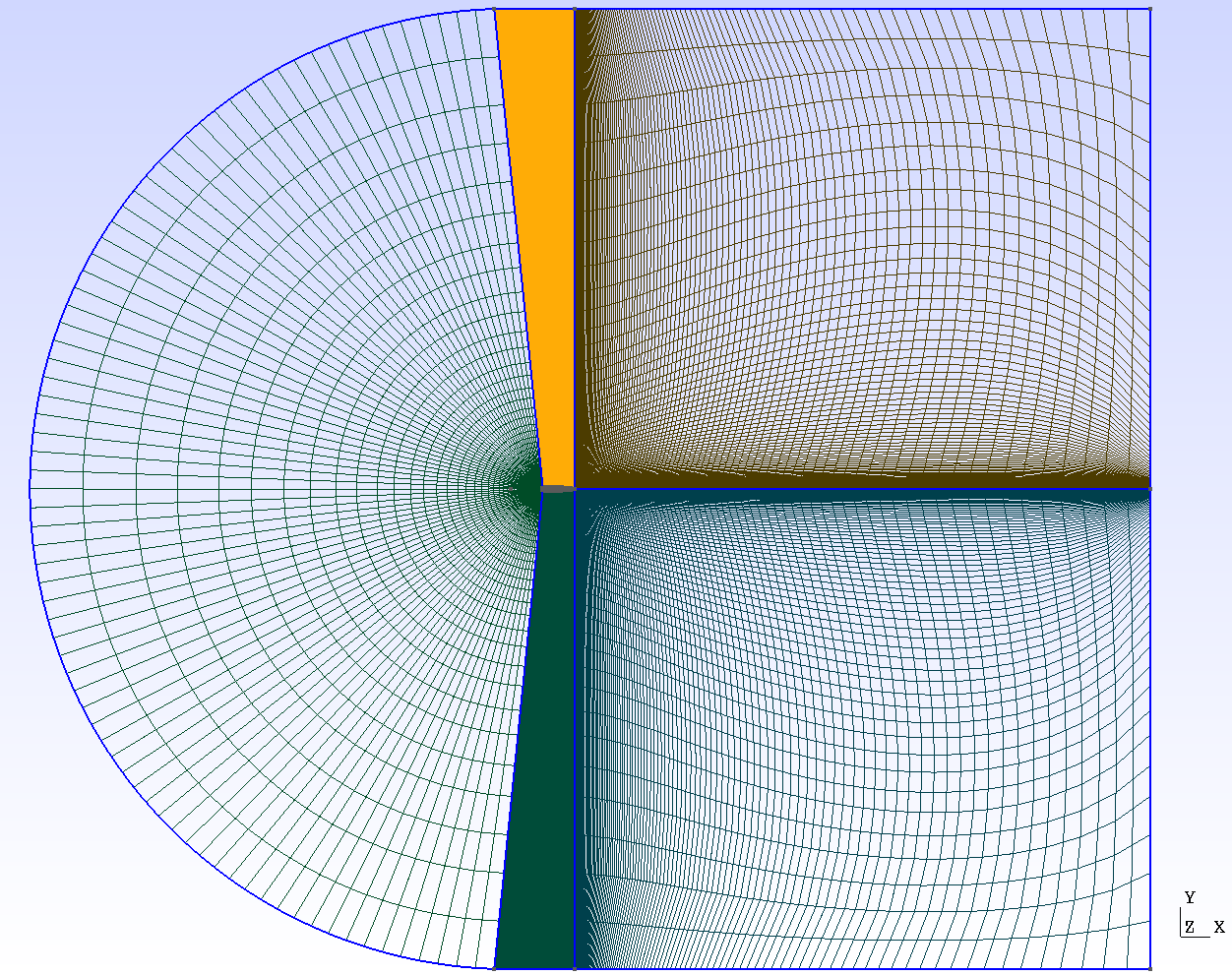

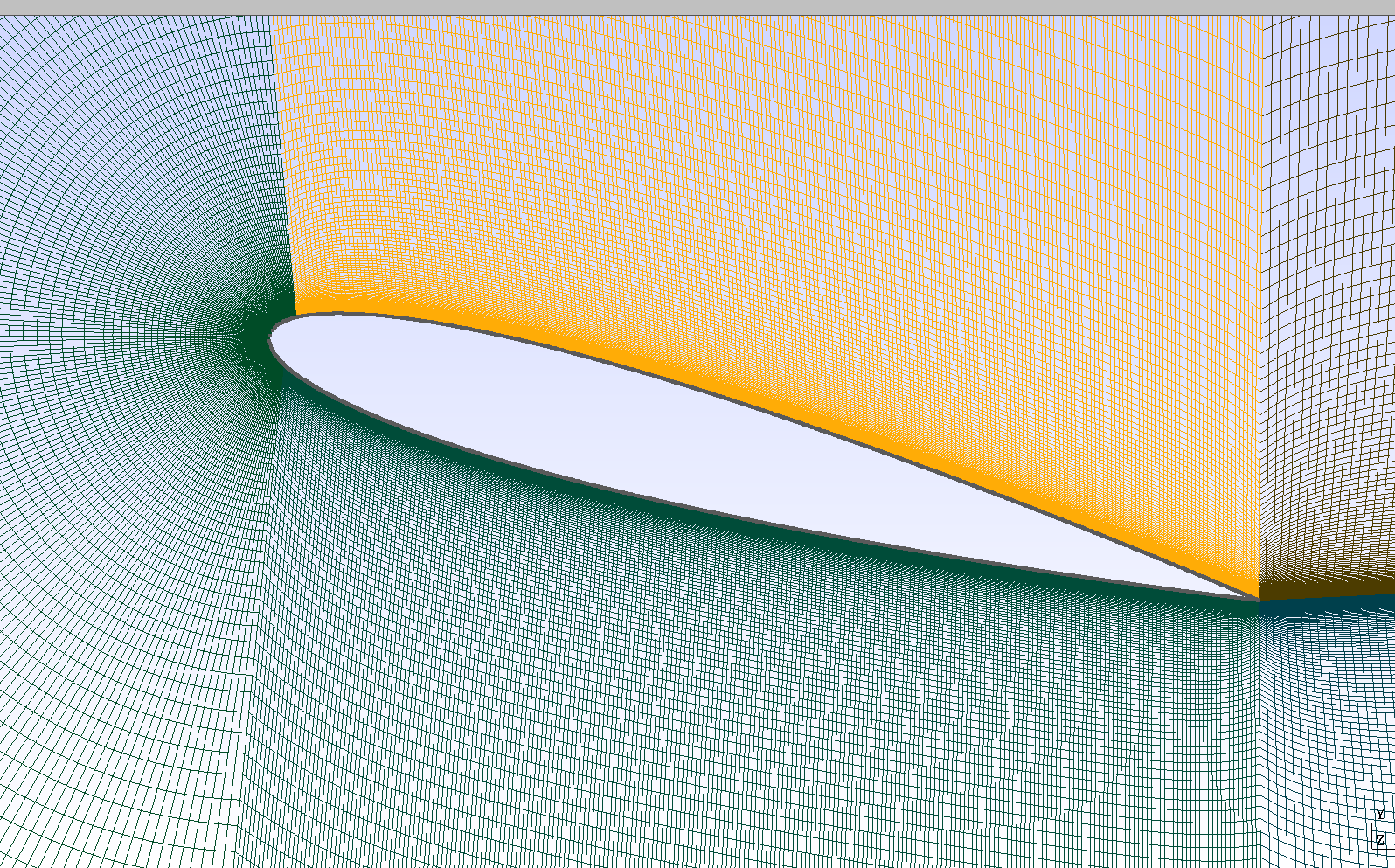

A C-Type mesh was created around the NACA. It is one of the usual types of mesh chosen for airfoils because it allows for the curvature of the grid to match the leading edge of the airfoil. Also, it allows the user to place more cells in areas which require higher resolution, typically near the upper and lower surfaces of the airfoil and in the wake. These properties are also true for O-type meshes, the difference being that the exterior boundary is a full circle, instead of a semi-circle in entry. In order to obtain such a mesh, the Transfinite functions of gmsh were used. To get a good understanding of how it was done, the reader is advised to read through the c_type_mesh.geo file included in the example, which is thoroughly commented on. To generate a mesh with a different angle of attack, the only thing required is to change the angle parameter in the c_type_mesh.geo file.

Note

Assuming that the gmsh executable is within your path, you can generate the mesh with:

subsection mesh

set type = gmsh

set file name = naca.msh

end

Below is the whole mesh and a zoom on the airfoil, for an angle of attack \(\alpha = 15°\)

Mesh Adaptation#

Mesh adaptation is used to get a higher resolution in areas of interest, that is to say, close to the airfoil, while keeping a coarse mesh far from the NACA. Since the mesh is big and the simulation lengthy in time, it was chosen not to refine too much. Also, since the area of interest of the mesh (close to the airfoil) is much smaller than the whole mesh, the coarsening fraction was set eight times bigger than the refinement fraction. The parameters were tuned as follows:

subsection mesh adaptation

set type = kelly

set variable = velocity

set fraction type = number

set max number elements = 700000

set max refinement level = 2

set min refinement level = 0

set frequency = 5

set fraction refinement = 0.02

set fraction coarsening = 0.16

end

Boundary Conditions#

The boundary conditions are defined as presented above:

subsection boundary conditions

set number = 4

subsection bc 0

set type = noslip

end

subsection bc 1

set type = function

subsection u

set Function expression = 1

end

subsection v

set Function expression = 0

end

subsection w

set Function expression = 0

end

end

subsection bc 2

set type = slip

end

subsection bc 3

set type = outlet

set beta = 1.3

end

end

The boundary 0, corresponding to the NACA0012 surface, is a noslip boundary condition that sets the velocity to zero on the boundary. Boundary 1 is the inlet where the velocity field was chosen to be horizontal and unitary to ensure that \(Re = 1000\) is correct. It is represented in green on the figure. Boundary 2, in black on the image, corresponds to the upper and lower walls which are endowed with a slip boundary condition. Finally, boundary 3 is of type outlet with a parameter \(\beta = 1.3\). The reader is referred to the Parameters Guide for more information about the \(\beta\) parameter.

Non-linear Solver#

The inexact_newton non-linear solver is used with a high tolerance, since convergence can be hard to obtain for high Reynolds numbers. This solver was chosen to reduce the cost of the simulation since it reuses the Jacobian matrix between iterations.

subsection non-linear solver

subsection fluid dynamics

set solver = inexact_newton

set verbosity = verbose

set tolerance = 1e-3

set max iterations = 10

end

end

Linear Solver#

Again, in order to reduce the computational time, the minimum residual for the linear solver was chosen higher than usual:

subsection linear solver

subsection fluid dynamics

set verbosity = verbose

set method = gmres

set relative residual = 1e-3

set minimum residual = 1e-8

set preconditioner = amg

set amg preconditioner ilu fill = 0

set amg preconditioner ilu absolute tolerance = 1e-12

set amg preconditioner ilu relative tolerance = 1.00

set max krylov vectors = 1000

end

end

Tip

It is important to note that the minimum residual of the linear solver is smaller than the tolerance of the non-linear solver. The reader can consult the Parameters Guide for more information.

Running the Simulations#

The simulation can be launched using the following command:

It can also run in parallel using:

with X the number of processors used to run it.

However, it is highly recommended to launch the simulation on a supercomputer. To launch on a desktop machine, the time end can be set to 3.0 to see the beginning of the simulation. However, to get relevant results about the forces, it is better to simulate at least for 10 seconds so that a pseudo-steady regime settles.

Results and Discussion#

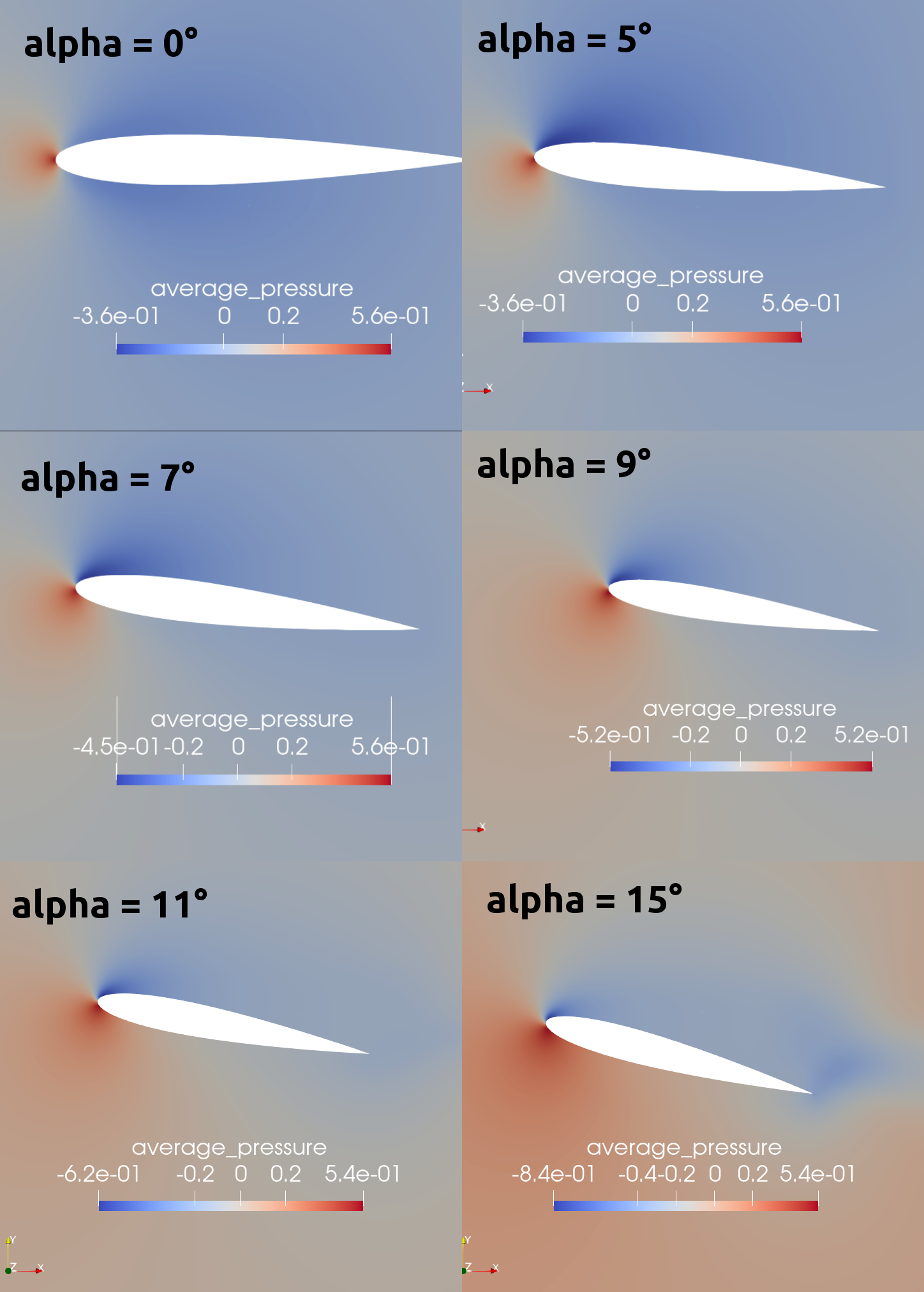

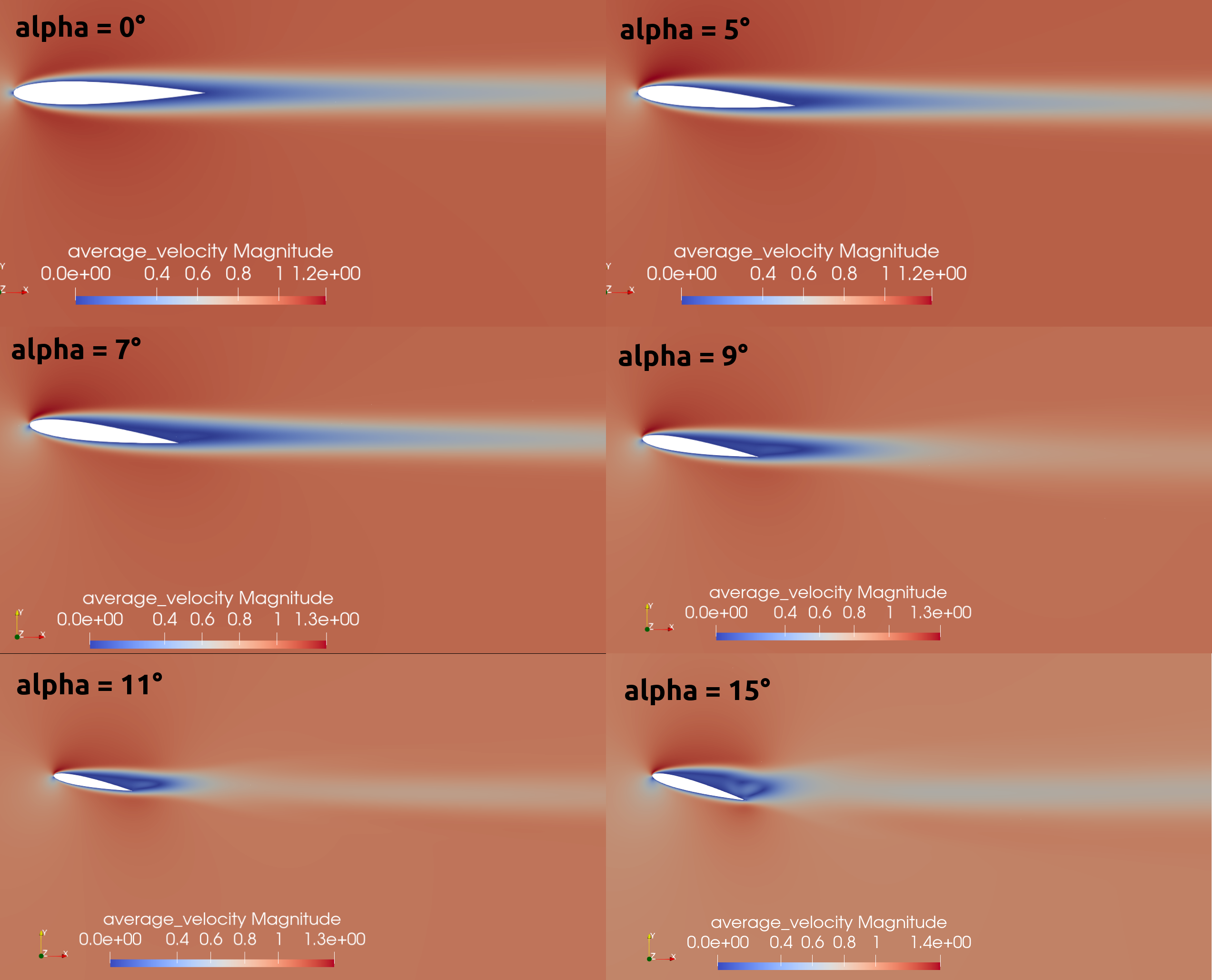

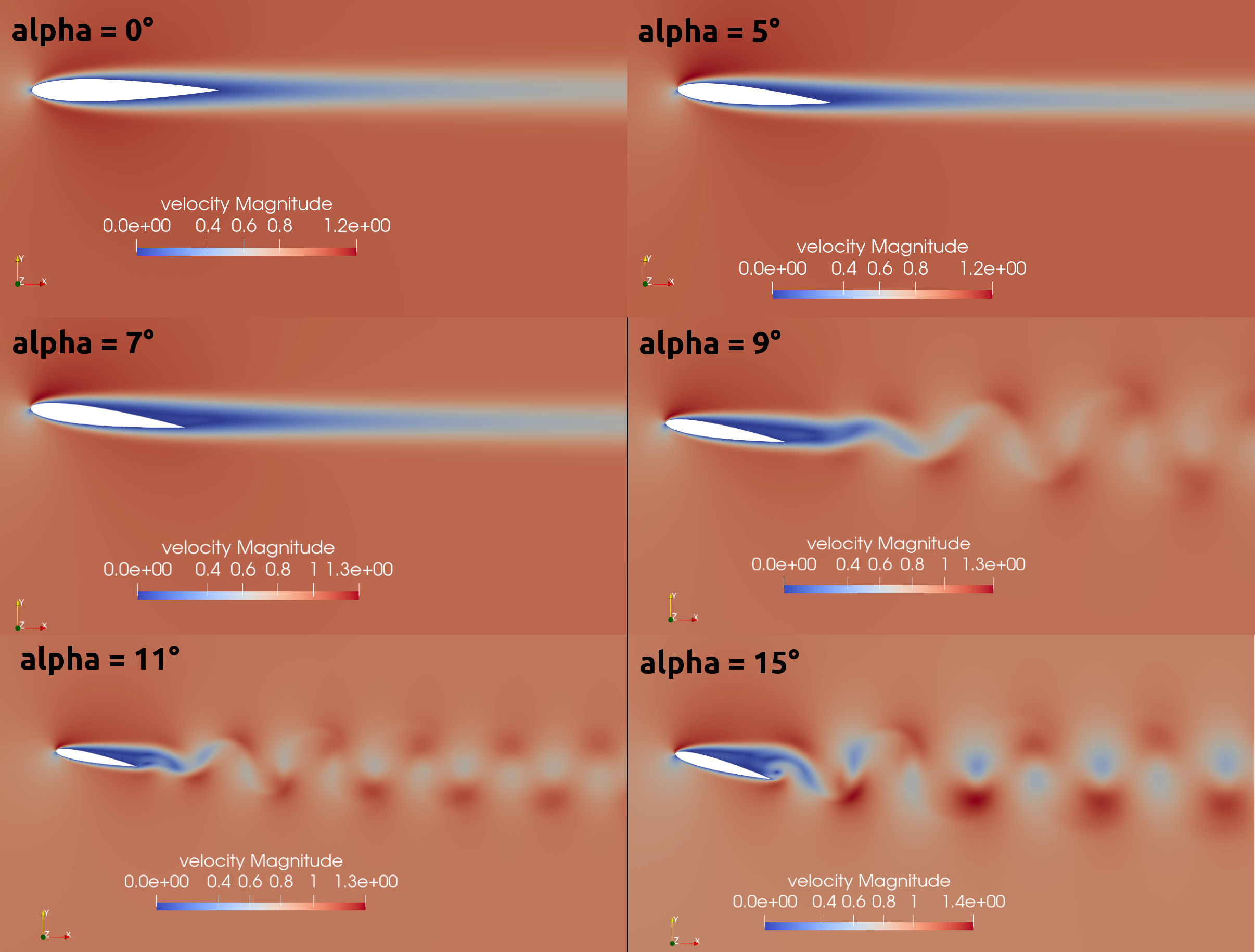

The following average pressure and velocity fields are obtained for an angle of attack \(\alpha\) such that \(\alpha \in \{0,5,7,9,11,15\}\):

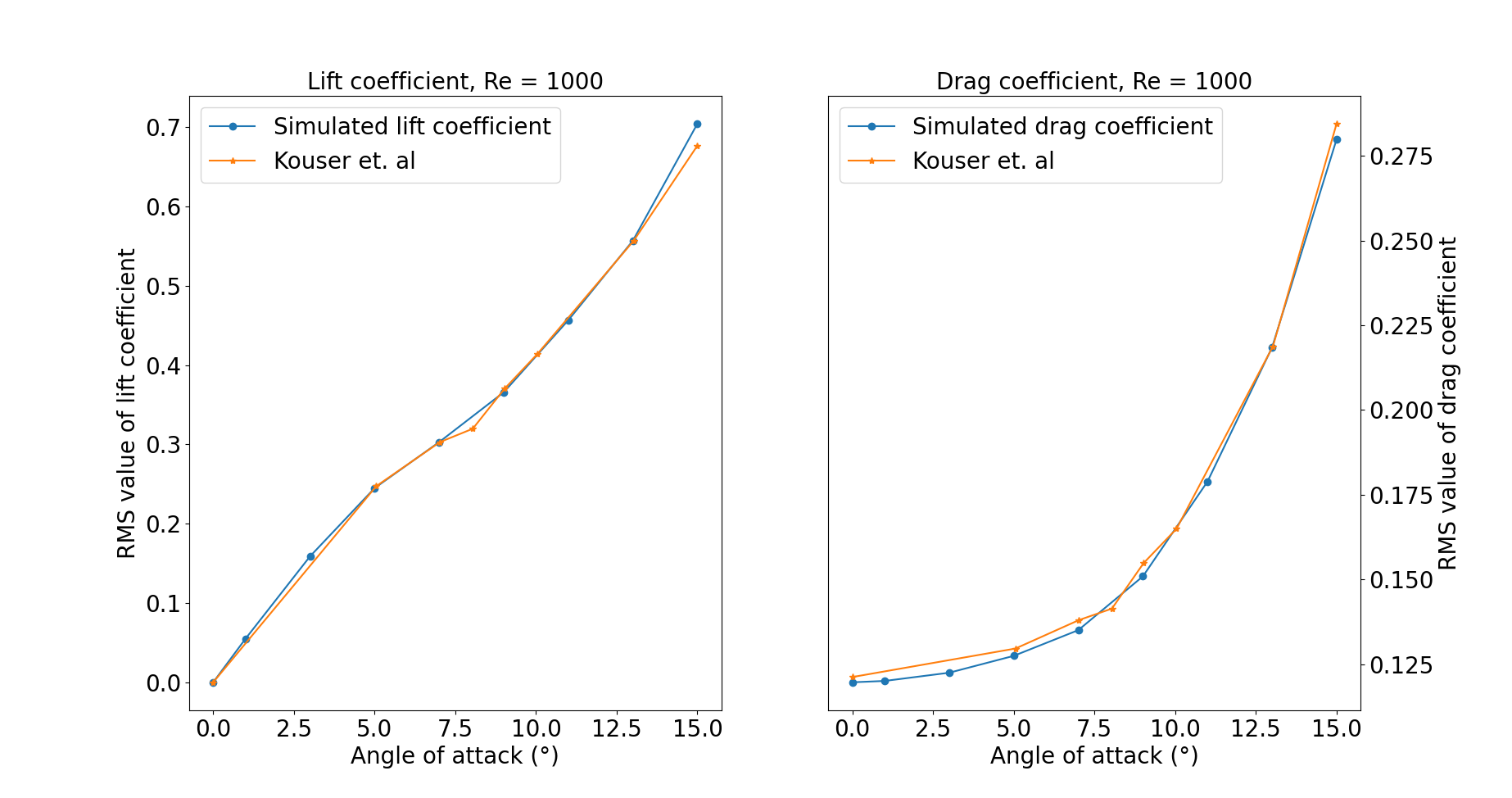

It is already noticeable that the higher the angle of attack, the greater the pressure gradient. Following this observation, the lift coefficient \(C_L\) is expected to increase with the angle of attack until stall condition is reached. The variation of the lift and drag coefficients are given below with a comparison to the work of Kouser et al. [1]. Both coefficients are computed using the following formula:

with \(F_L\) and \(F_D\), respectively, the lift and drag forces. Those forces can be obtained in the force.00.dat and post-processed using the postprocessing.py python file included in the folder of this example. \(S\) represents a reference area; here, it is equal to the product of the chord length \(C\) (equal to 1 in this example) multiplied by a unitary transversal length.

The results obtained fit the drag and lift coefficients found by Kouser et al. [1]. Note that the value given for the \(C_D\) and \(C_L\) coefficients are Root Mean Squared (RMS) values. The time span considered is 25s long (between 15 \(\text{s}\) and 40 \(\text{s}\)). The first 15 seconds were not considered to let the system reach a pseudo-steady state.

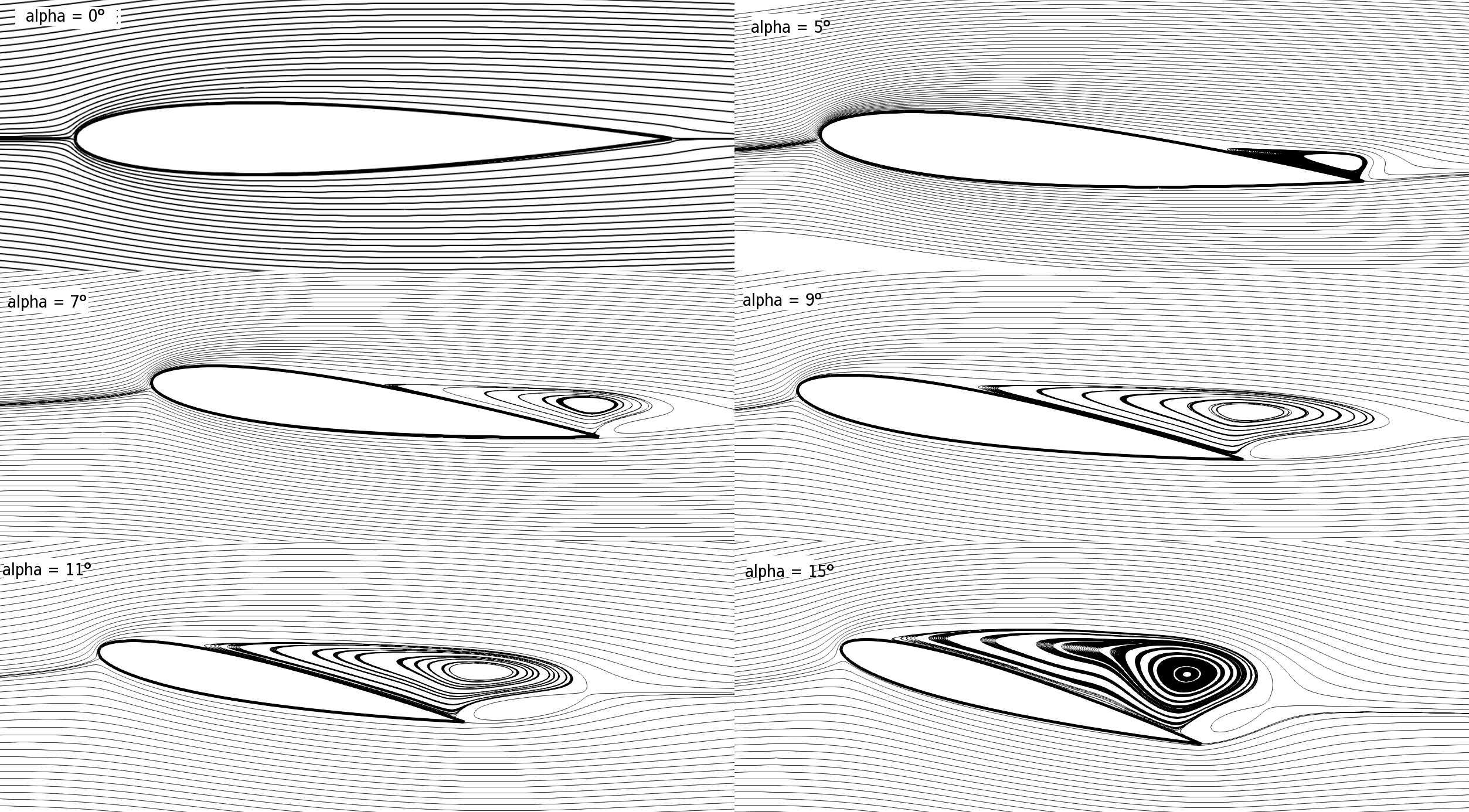

One can also see the low-velocity zones on the upper part of the airfoil, which corresponds to the recirculating zone: the noslip condition on the NACA imposes a zero velocity condition on the fluid. The following streamline representation helps to see the movements of the fluid inside the recirculating zone:

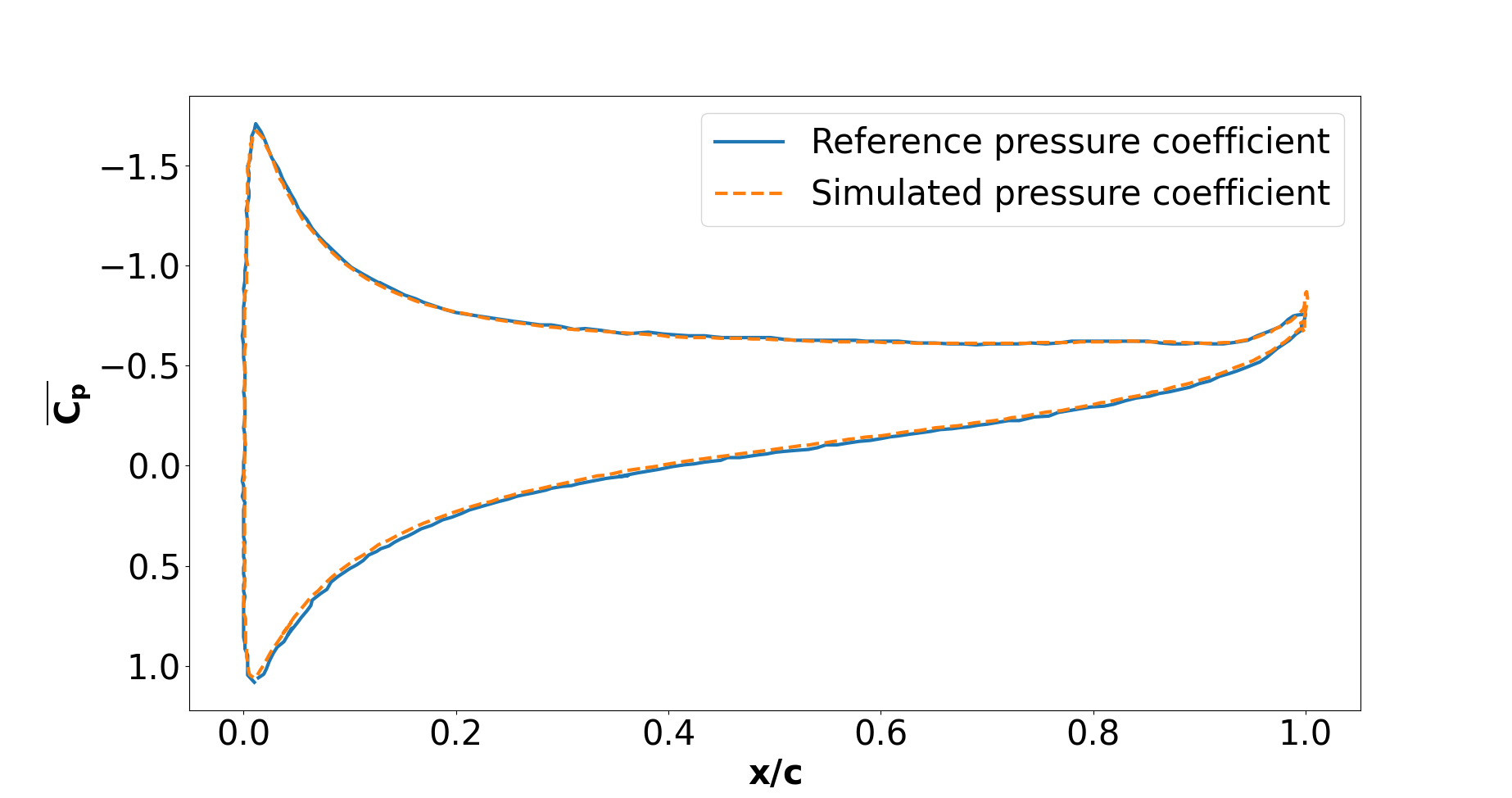

It can be observed that zones of recirculation form on the airfoil. This is due to two phenomena: first the flow outside of the boundary layer tends to “pull” it in its direction, and the noslip boundary condition slows the fluid, then a positive pressure gradient, commonly referred to as adverse pressure gradient, on the upper surface pushes the fluid backward. Following this, the boundary layer separates, and a recirculation zone is formed. Below is represented the mean pressure coefficient \(C_p\) on the airfoil with a comparison to the literature. It is computed using the following formula:

with \(p_{\infty}\) the static pressure in the freestream (equal to 0 in this case), \(\rho_{\infty}\) the freestream fluid density, equal to the fluid density since we are solving an incompressible flow and \(u_{\infty}\) the freestream velocity of the fluid, equal to 1.0 in this case.

The important pressure at the leading edge of the airfoil is what allows the incoming flow to be deflected to the upper and lower surfaces. Then, if we look at the upper surface (be careful about the reversed y-axis) the adverse pressure gradient is visible. Then at the trailing edge, the mesh is not precise enough. This zone of high pressure gradient, though not physically accurate, does not invalidate the whole result.

For angles of attack \(\alpha\geq 9°\), the vortices start to detach from the airfoil. It can be seen using the instantaneous velocity fields. The velocity fields for each angle of attack, at t = 40 seconds, are shown below:

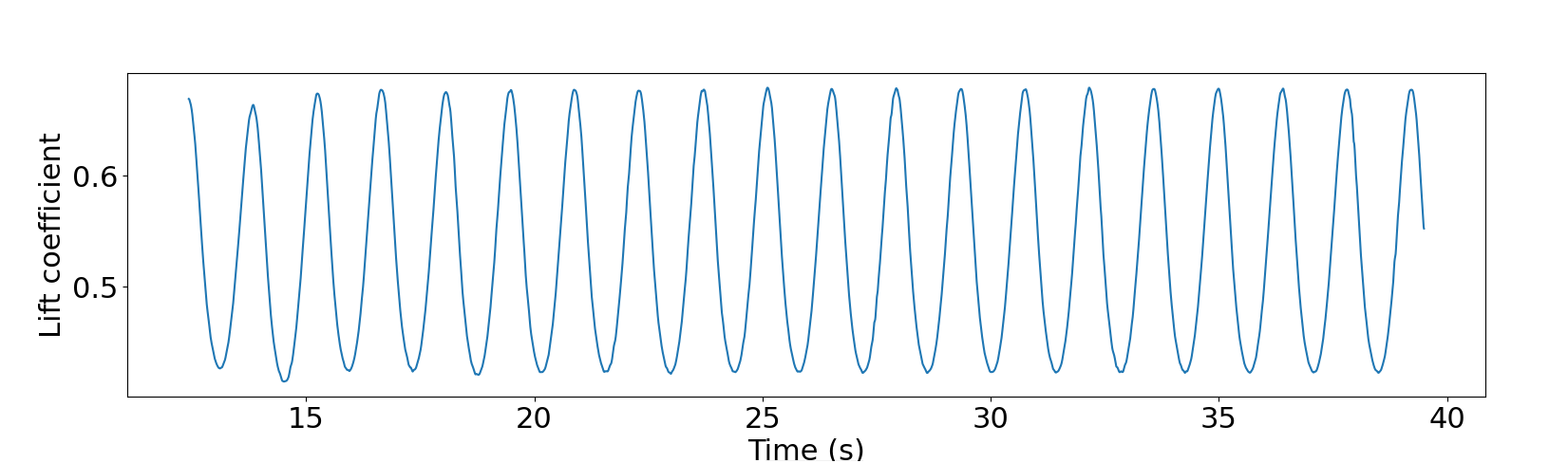

In order to retrieve the frequency of the vortex shedding, one can look at the fluctuations of \(C_L\), as presented below for the case where \(\alpha=15°\) was considered:

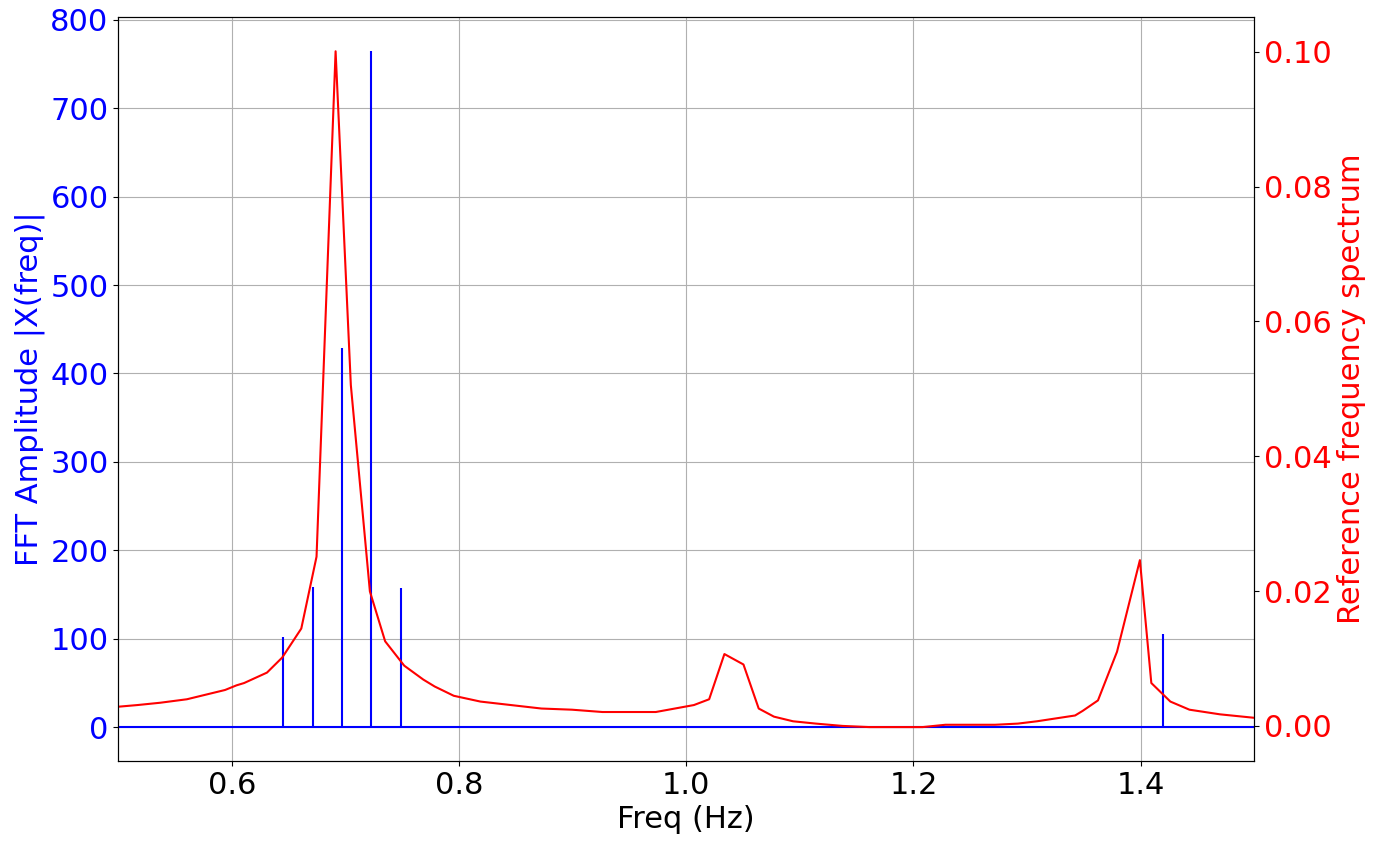

The best mathematical tool available to make a spectral analysis is a Fourier transform, which is performed below, with literature results (Kouser et al. (2021) [1]) for comparison:

The fundamental frequency is \(f_1=0.72 \ \text{Hz}\), which gives a shedding period \(T = 1.39 \ \text{s}\) that is coherent with the instantaneous velocity field above.

Possibilities for Extension#

High-order elements: In order to get more precise results on the forces and the coefficients, Q2-Q2 elements may be used. It can be modified by setting

set velocity order = 2andset pressure order = 2in theFEMsubsection ofnaca.prm.Going 3D: the mesh can be extruded into the third dimension. Some modifications will be required in the boundary conditions, and getting the correct boundaries id is not trivial. However, with periodic boundary conditions set on the sides of the box, spanwise effects can be taken into account, which should yield much better results.

Validate for higher Reynolds numbers: Literature is available for comparison at \(Re=10000\) at Yamaguchi et al. (2013) [2] and \(Re=23000\) at Kojima et al. (2013) [3].