Cooling Fin#

This example simulates the heat transfer in a cooling fin, which is a classical problem in heat transfer

Features#

Solver:

lethe-fluidHeat transfer

Usage of a python script for post-processing data

Files Used in This Example#

Both files mentioned below are located in the example’s folder (examples/multiphysics/cooling-fin).

Parameter file:

fin.prmPostprocessing python script:

compare_solution.py

Description of the Case#

A cylindrical fin of length \(L=0.2\) and radius \(R=0.01\) is fixed to a wall at a constant temperature \(T_b=100\). The radial surface of the fin is subject to natural convection following Newton’s law of cooling with \(h=10\) and \(T_{\infty}=20\). The material from which the fin is made has a thermal conductivity \(k=100\mathrm{W/m/K}\). The geometry of this example is illustrated below.

In the case where the Biot number \(\mathrm{Bi}=\frac{hR}{k}<1\), the temperature distribution in the fin can be assumed to vary only along the \(x\) direction and is approximated very adequately by the following equation [1]:

where \(\beta=\sqrt{\frac{hP}{kA}}\) is the fin parameter, \(P\) is the perimeter of the fin, and \(A\) is the cross-sectional area of the fin.

Parameter File#

Simulation Control#

The simulation is done in steady state without mesh adaptation.

subsection simulation control

set method = steady

set output name = out

set output path = ./output/

end

Multiphysics#

The multiphysics subsection is used to to disable fluid dynamics and enable the heat transfer physics.

subsection multiphysics

set fluid dynamics = false

set heat transfer = true

end

Boundary Conditions#

Boundary conditions must be set for both fluid dynamics and heat transfer, even though the former is not used.

Boundary Conditions - Fluid Dynamics#

For the fluid dynamics, we set the boundary conditions to no-slip on all the boundaries.

subsection boundary conditions

set number = 3

subsection bc 0

set id = 0

set type = noslip

end

subsection bc 1

set id = 1

set type = noslip

end

subsection bc 2

set id = 2

set type = noslip

end

end

Boundary Conditions - Heat Transfer#

For the heat transfer, we set the boundary conditions as follows:

subsection boundary conditions heat transfer

set number = 3

subsection bc 0

set id = 0

set type = convection-radiation-flux

subsection h

set Function expression = 10

end

subsection Tinf

set Function expression = 20

end

subsection emissivity

set Function expression = 0

end

subsection heat_flux

set Function expression = 0

end

end

subsection bc 1

set id = 1

set type = temperature

subsection value

set Function expression = 100

end

end

subsection bc 2

set id = 2

set type = convection-radiation-flux

subsection h

set Function expression = 0

end

subsection Tinf

set Function expression = 20

end

subsection emissivity

set Function expression = 0

end

subsection heat_flux

set Function expression = 0

end

end

end

Physical Properties#

In the physical properties subsection, we define the properties of the fin. The thermal conductivity is set to \(k=100\). Even though the fin is technically a solid, by default Lethe calls fluid the material which is used in the simulation domain when there is only one material.

subsection physical properties

set number of fluids = 1

subsection fluid 0

set thermal conductivity = 100

end

end

Mesh#

In the mesh subsection, we define a cylinder with the appropriate dimensions. We use the subdivided_cylinder grid generator to manually control the number of division on the axial direction of the cylinder. The mesh is initially refined \(3\) times to ensure that it is sufficiently fine.

subsection mesh

set type = dealii

set grid type = subdivided_cylinder

set grid arguments = 10 : 0.01 : 0.1

set initial refinement = 3

end

FEM#

We use the FEM subsection to define the order of the finite element method used in the simulation. We set the order to 2 for the temperature field.

subsection FEM

set temperature order = 2

end

Postprocessing#

We calculate the heat fluxes on the boundaries of the fin.

subsection post-processing

set verbosity = verbose

set calculate heat flux = true

end

Running the Simulation#

We can call lethe-fluid by invoking the following command:

Note

This simulation should take less than a minute if Lethe is compiled in release mode

Results#

A postprocessing script is provided with the example. It extracts the axial temperature profile in the fin and compares it with the analytical solution. The script can be run by invoking the following command and specifying the vtu output file:

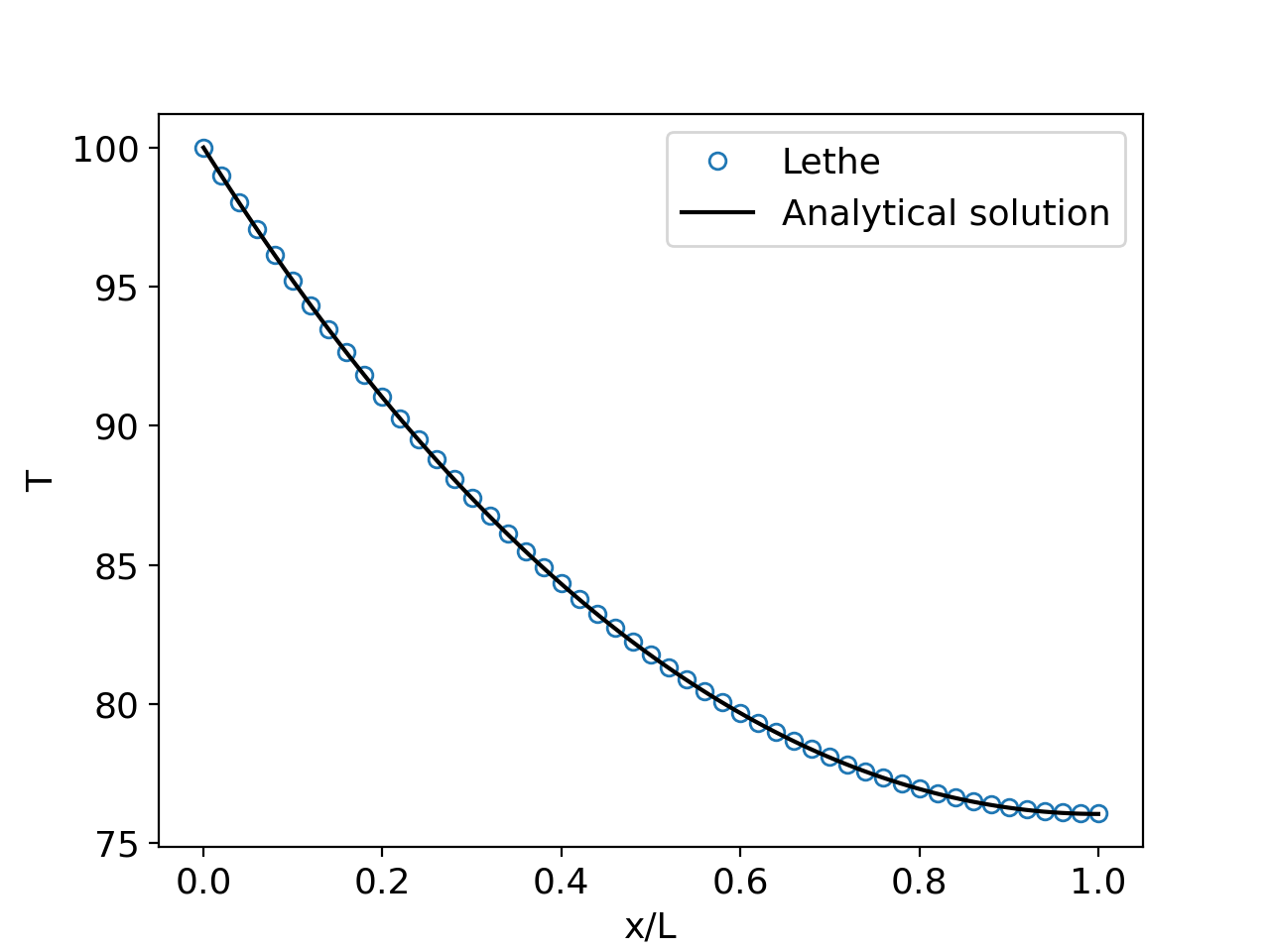

The following figure shows the temperature distribution in the fin. The analytical solution is also plotted for comparison. The agreement between the simulation and analytical results is excellent.

The postprocessing script also calculates the heat fluxes on the boundaries of the fin. The following table shows the heat fluxes calculated by the simulation and the analytical solution.

Boundary |

Simulation (W) |

Analytical (W) |

|---|---|---|

Radial surface of the fin |

8.019 |

8.020 |

Base of the fin |

8.019 |

8.020 |

We see that even with a relatively coarse mesh, the heat fluxes calculated by the simulation are very close to the analytical solution.

Possibilities for Extension#

The heat flux is sensitive to the finite element order used for the temperature field. Try the simulations again with first-order Q1 elements and compare the results.