Plate Discharge#

This example compares the angles of repose and performance results of a plate discharging particles with performance enhancement methods.

Features#

Solvers:

lethe-particlesThree-dimensional problem

Post-processes results and compares them to the literature

Files Used in this Example#

All the files mentioned below are located in the example folder examples/dem/3d-plate-discharge.

There are 4 parameters files: a baseline case and three other cases with different features using one or a combination of performance enhancing methods. The parameters files are:

Name of the .prm file

plate-discharge_base.prmplate-discharge_asc.prm×

plate-discharge_lb.prm×

plate-discharge_asc-lb.prm×

×

These parameters files are ready for the simulations. We run 2 sets of simulation: performance and data. In the performance simulations, speedup is computed. Hence, the writing of solution files is deactivated. In the data simulations, those files are outputted to analyze the results. The performance analysis parameter files are in the folder

performance/, and the ones for the data analysis are in the folderdata/.

Description of the Case#

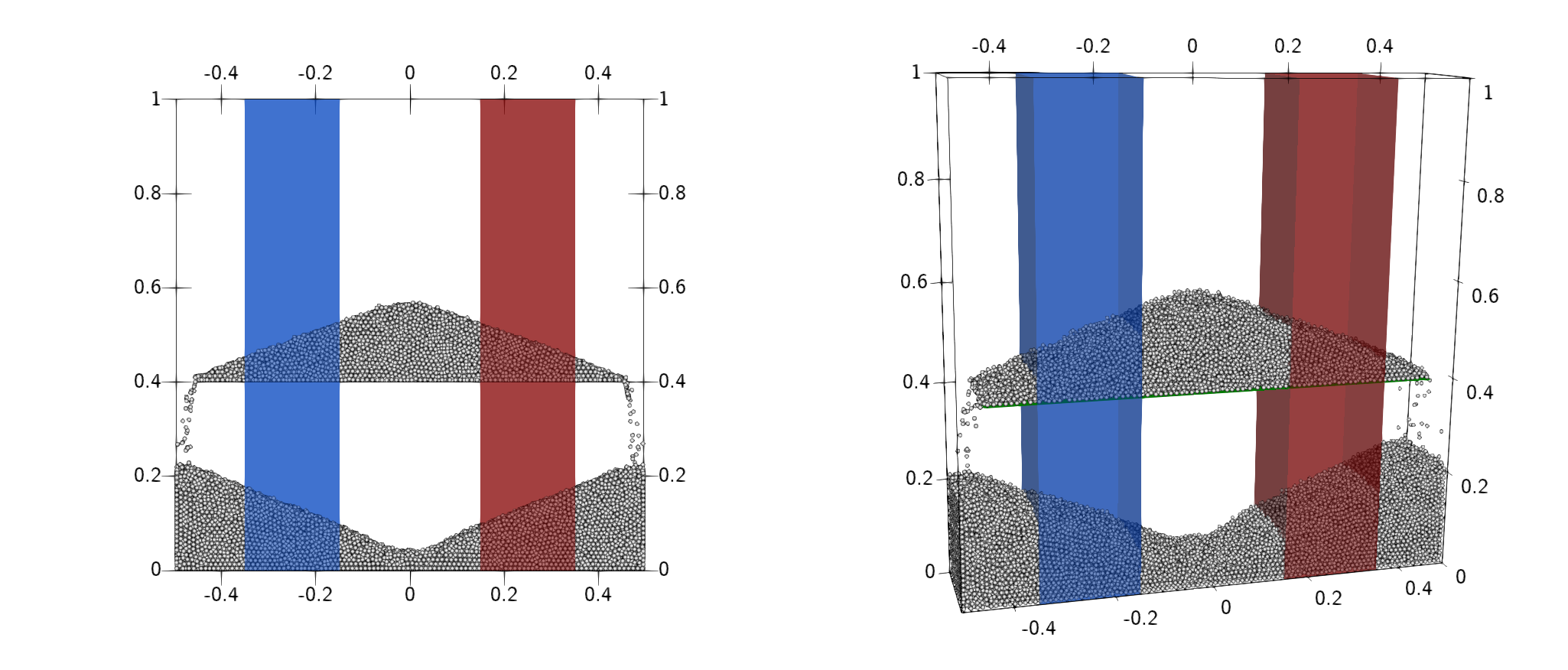

This example simulates the discharge of particles at the sides of a plate in a rectangular container in order to get the angle of repose of the granular material as done by Zhou et al. [1] The example compares the angles of repose and the performance of the simulations with the use of adaptive sparse contacts and load balancing methods. The angles are also compared to literature values.

Diagram of the container (black) with the plate (green) and the particles (blue).#

DEM Parameter files#

Baseline case simulation#

In this section, we introduce the different sections of the parameter file plate-discharge_base.prm which do not use any performance enhancement methods.

Simulation Control#

The simulation lasts \(15 \ \text{s}\) and the DEM time step is \(0.0001 \ \text{s}\). The output are generated every \(0.01 \ \text{s}\) for the simulation for data analysis.

subsection simulation control

set time step = 1e-4

set time end = 15

set log frequency = 500

set output frequency = 100

set output path = ./output_base/

end

Mesh#

The rectangular container is a \(1.0 \times 1.0 \times 0.2 \ \text{m}\) box.

subsection mesh

set type = dealii

set grid type = subdivided_hyper_rectangle

set grid arguments = 5,5,1 : -0.5, 0.0, 0.0 : 0.5, 1.0, 0.2 : true

set initial refinement = 3

end

Solid Objects#

The plate is a solid object with a simple mesh of 2 triangles placed at a height of \(0.4 \ \text{m}\) in the container.

subsection solid objects

subsection solid surfaces

set number of solids = 1

subsection solid object 0

subsection mesh

set type = gmsh

set file name = plate.msh

set simplex = true

set initial translation = 0, 0.4, 0

end

end

end

end

Lagrangian Physical Properties#

The lagrangian properties are relatively arbitrary. The simulation contains \(52000\) particles with a diameter of \(0.01 \ \text{m}\), and a density of \(2400 \ \frac{\text{kg}}{\text{m}^3}\). Both properties of particle-particle and particle-wall interactions are the same.

subsection lagrangian physical properties

set g = 0, -9.81, 0.0

set number of particle types = 1

subsection particle type 0

set size distribution type = uniform

set diameter = 0.01

set number of particles = 52000

set density particles = 2400

set young modulus particles = 1e6

set poisson ratio particles = 0.3

set restitution coefficient particles = 0.9

set friction coefficient particles = 0.2

set rolling friction particles = 0.1

end

set young modulus wall = 1e6

set poisson ratio wall = 0.3

set restitution coefficient wall = 0.9

set friction coefficient wall = 0.2

set rolling friction wall = 0.1

end

Insertion Info#

The particles are inserted above the plate with the volume insertion method.

subsection insertion info

set insertion method = volume

set inserted number of particles at each time step = 52000

set insertion frequency = 20000

set insertion box points coordinates = -0.45, 0.4, 0 : 0.45, 1.0, 0.2

set insertion distance threshold = 1.25

set insertion maximum offset = 0.1

set insertion prn seed = 20

set insertion direction sequence = 0, 2, 1

end

Floating Walls#

At the beginning of the simulation, floating walls are placed vertically at both extremities of the plate to keep all particles on the latter. The walls are removed suddenly after \(0.75 \ \text{s}\) of simulation, starting the discharge.

subsection floating walls

set number of floating walls = 2

subsection wall 0

set point on wall = -0.45, 0., 0.

set normal vector = 1., 0., 0.

set start time = 0

set end time = 0.75

end

subsection wall 1

set point on wall = 0.45, 0., 0.

set normal vector = 1., 0., 0.

set start time = 0

set end time = 0.75

end

end

Model Parameters#

The model parameters are quite standard for a DEM simulation with the non-linear Hertz-Mindlin contact force model, a constant rolling resistance torque, and the velocity Verlet integration method. For the baseline case, we do not use any performance enhancement method.

subsection model parameters

subsection contact detection

set contact detection method = dynamic

set dynamic contact search size coefficient = 0.9

set neighborhood threshold = 1.3

end

subsection load balancing

set load balance method = none

end

set particle particle contact force method = hertz_mindlin_limit_overlap

set rolling resistance torque method = constant

set particle wall contact force method = nonlinear

set integration method = velocity_verlet

subsection adaptive sparse contacts

set enable adaptive sparse contacts = false

end

subsection load balancing

set load balance method = none

end

end

Timer#

The timer is enabled since we want to profile the computational performance of the simulations. We print the total wallclock time elapsed since the start at every log frequency iteration.

subsection timer

set type = iteration

end

ASC Simulation#

The only differences between plate-discharge_base.prm and plate-discharge_asc.prm are the enabling of the ASC and the name of the folder for outputs.

Model Parameters#

Here the ASC is enabled with a granular temperature threshold of \(0.0001 \ \frac{\text{m}^2}{\text{s}^2}\) and a solid fraction threshold of \(0.4\). Those parameters have shown to be efficient in other DEM simulations with a good balance between performance gain and low impact on the simulation results. These parameters can be adjusted.

subsection model parameters

subsection contact detection

set contact detection method = dynamic

set dynamic contact search size coefficient = 0.9

set neighborhood threshold = 1.3

end

set particle particle contact force method = hertz_mindlin_limit_overlap

set rolling resistance torque method = constant

set particle wall contact force method = nonlinear

set integration method = velocity_verlet

subsection adaptive sparse contacts

set enable adaptive sparse contacts = true

set granular temperature threshold = 1e-4

set solid fraction threshold = 0.4

end

subsection load balancing

set load balance method = none

end

end

Load Balancing Simulation#

The only differences between plate-discharge_base.prm and plate-discharge_lb.prm are the usage of the load balancing and the name of the folder for outputs.

Model Parameters#

Here, the dynamic load balancing checks if a load balancing is needed every \(2500\) iterations with a load threshold of \(0.5\).

subsection model parameters

subsection contact detection

set contact detection method = dynamic

set dynamic contact search size coefficient = 0.9

set neighborhood threshold = 1.3

end

set particle particle contact force method = hertz_mindlin_limit_overlap

set rolling resistance torque method = constant

set particle wall contact force method = nonlinear

set integration method = velocity_verlet

subsection adaptive sparse contacts

set enable adaptive sparse contacts = false

end

subsection load balancing

set load balance method = dynamic

set threshold = 0.5

set dynamic check frequency = 2500

end

end

ASC with Load Balancing Simulation#

The only differences between plate-discharge_base.prm and plate-discharge_asc-lb.prm are the usage of the ASC method with the load balancing, and the name of the folder for outputs.

Model Parameters#

Here, we use the ASC with the dynamic load balancing, using the same load balancing parameters. In this case, the mobility status of the cells from the ASC will influence the weight, i.e. the computational contribution of the cell in the load balancing evaluation. The additional parameters for active cells weight factor is \(0.7\), and the inactive cells weight factor is \(0.5\), while the mobile cells always have a fixed weight factor of \(1\).

subsection model parameters

subsection contact detection

set contact detection method = dynamic

set dynamic contact search size coefficient = 0.9

set neighborhood threshold = 1.3

end

set particle particle contact force method = hertz_mindlin_limit_overlap

set rolling resistance torque method = constant

set particle wall contact force method = nonlinear

set integration method = velocity_verlet

subsection adaptive sparse contacts

set enable adaptive sparse contacts = true

set granular temperature threshold = 1e-4

set solid fraction threshold = 0.4

end

subsection load balancing

set load balance method = dynamic_with_sparse_contacts

set threshold = 0.5

set dynamic check frequency = 2500

set active weight factor = 0.7

set inactive weight factor = 0.5

end

end

Running the Simulations#

Simulations can be launched individually with the executable lethe-particles and the parameter files, while saving the display in the terminal in a log file.

To make things easier a script is provided to run all the simulations in a sequence from the dem/3d-plate-discharge/ folder.

In order to run the simulations for the performance analysis, you can use the following command:

Which corresponds to:

simulations=("base" "asc" "lb" "asc-lb")

cd performance/

for sim in "${simulations[@]}"

do

echo "Running the $sim simulation"

time mpirun -np 8 lethe-particles plate-discharge_$sim.prm | tee log_$sim.out

done

Or you can run the simulations in the performance/ folder with the following commands:

In order to run the simulations for the data analysis, you can use the following script:

Note

Running the simulations for the performance analysis using 8 cores takes between 25 and 45 minutes per simulation, for a total of around 2 hours. Running the simulations for data analysis takes a few minutes longer per simulation.

Results#

The simulations should look like the following video:

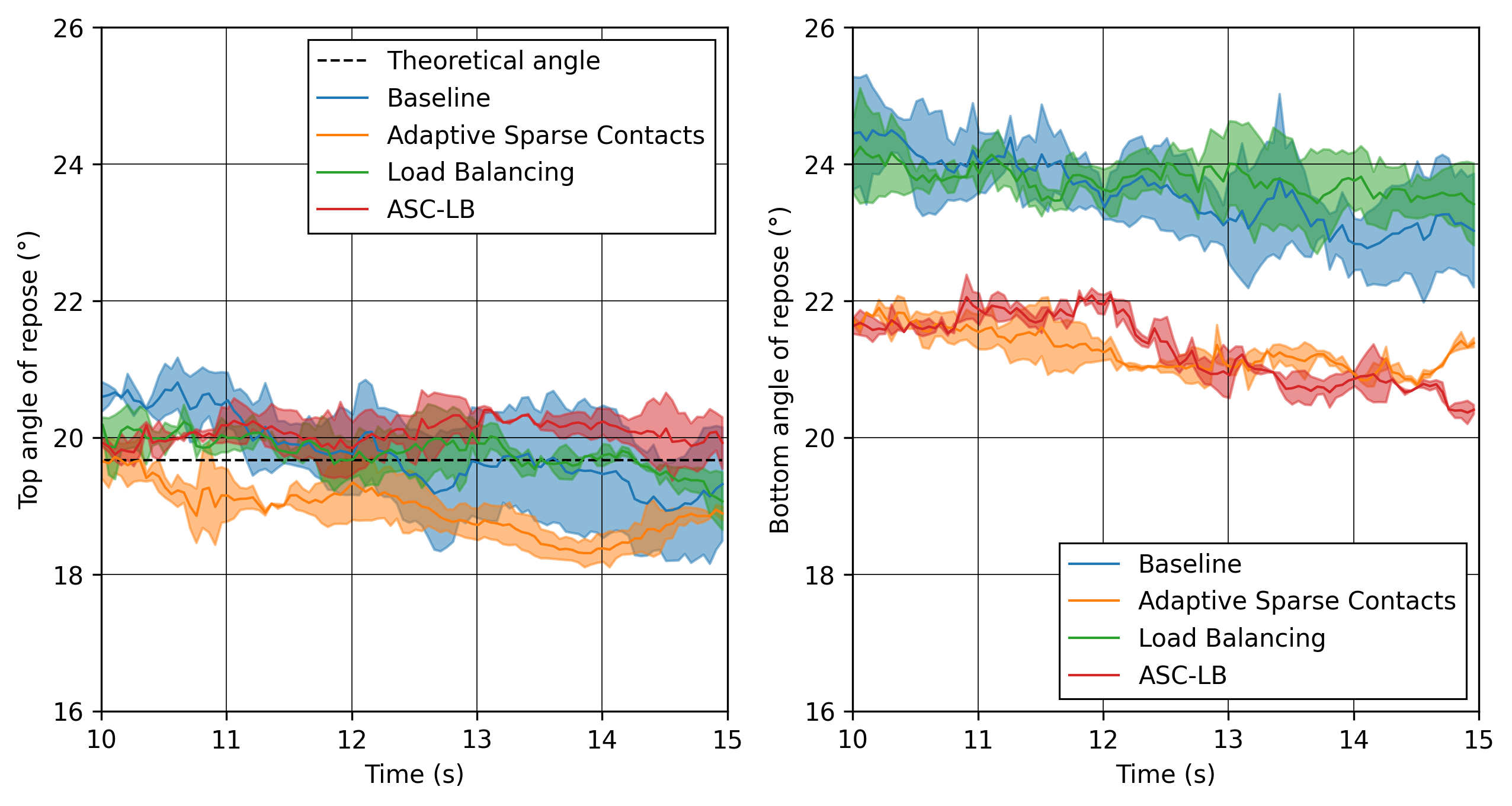

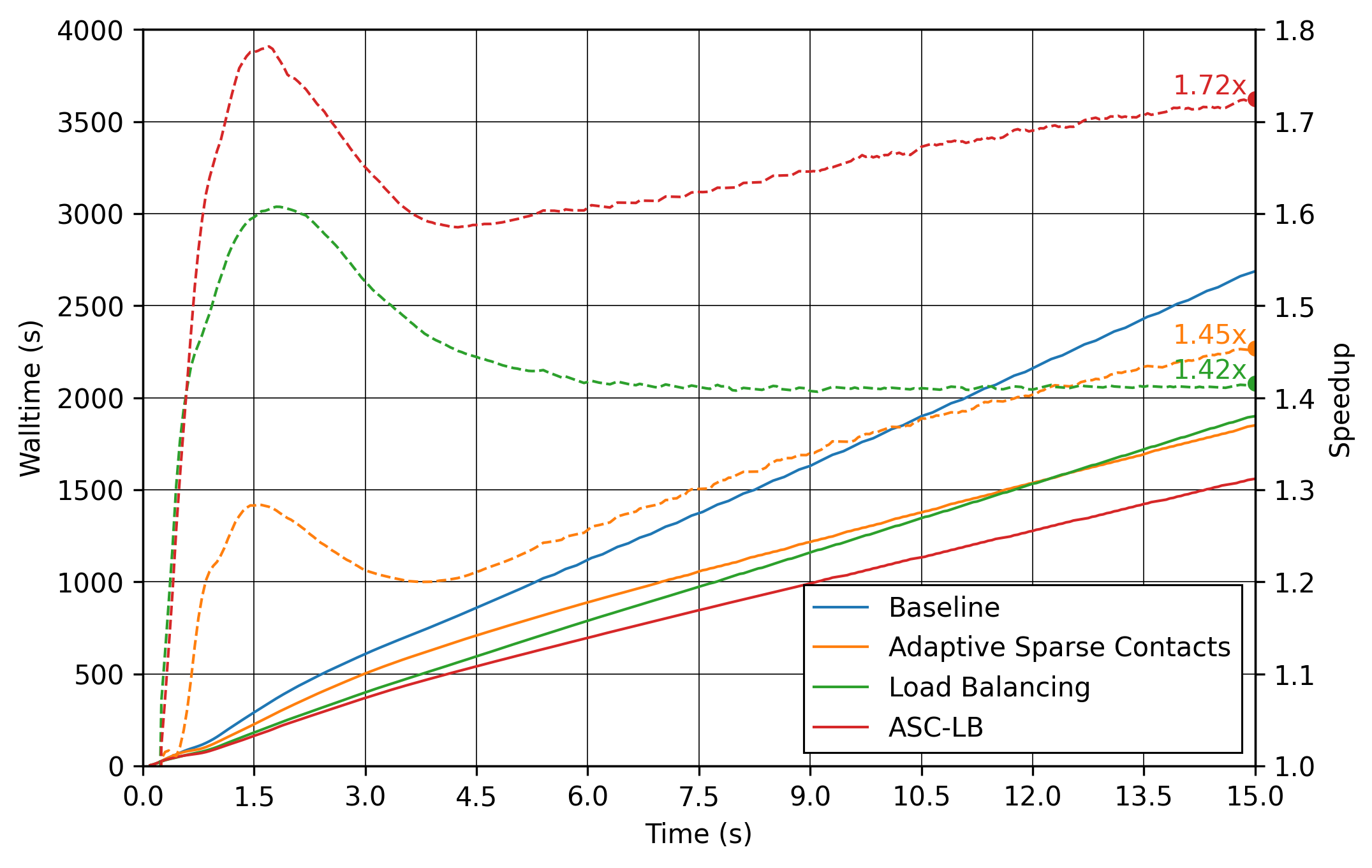

The data is extracted with the Lethe PyVista tool and post-processed with custom functions in the files The script will generate the figures. If you want to modify the path or the filenames, you have to modify the script. The log files (outputs displayed in the terminal) are read to extract the simulation and wall times. The speedup is calculated with the baseline case as the reference. The results are plotted in the following figure, where the solid lines show the walltime during the simulation, the dashed lines show the speedup, and the points show to total speedup. The walltime during the simulations (solid line) and the speedup (dashed line) for the performance enhancement methods with the Adaptive Sparse Contacts (ASC) and the Load Balancing (LB) compared to the baseline case.# Note The slight oscillations of the speedup are caused by the scientific notation format of the walltime by the timer feature after \(1000 \ \text{s}\). The walltimes are attenuated by the moving average, but the division operation for the speedup accentuates the lack of time precision. The load balancing method helps the performance of the simulation from the start, since the particles move within the domain during the discharge. The load balancing allows to distribute the particles, and therefore all their related computations, more evenly between the cores. Once the discharge of the particles is mostly done and only a few particles are still falling from the top part, the performance gain brought by the load balancing stays constant since the load across the cores is already balanced.

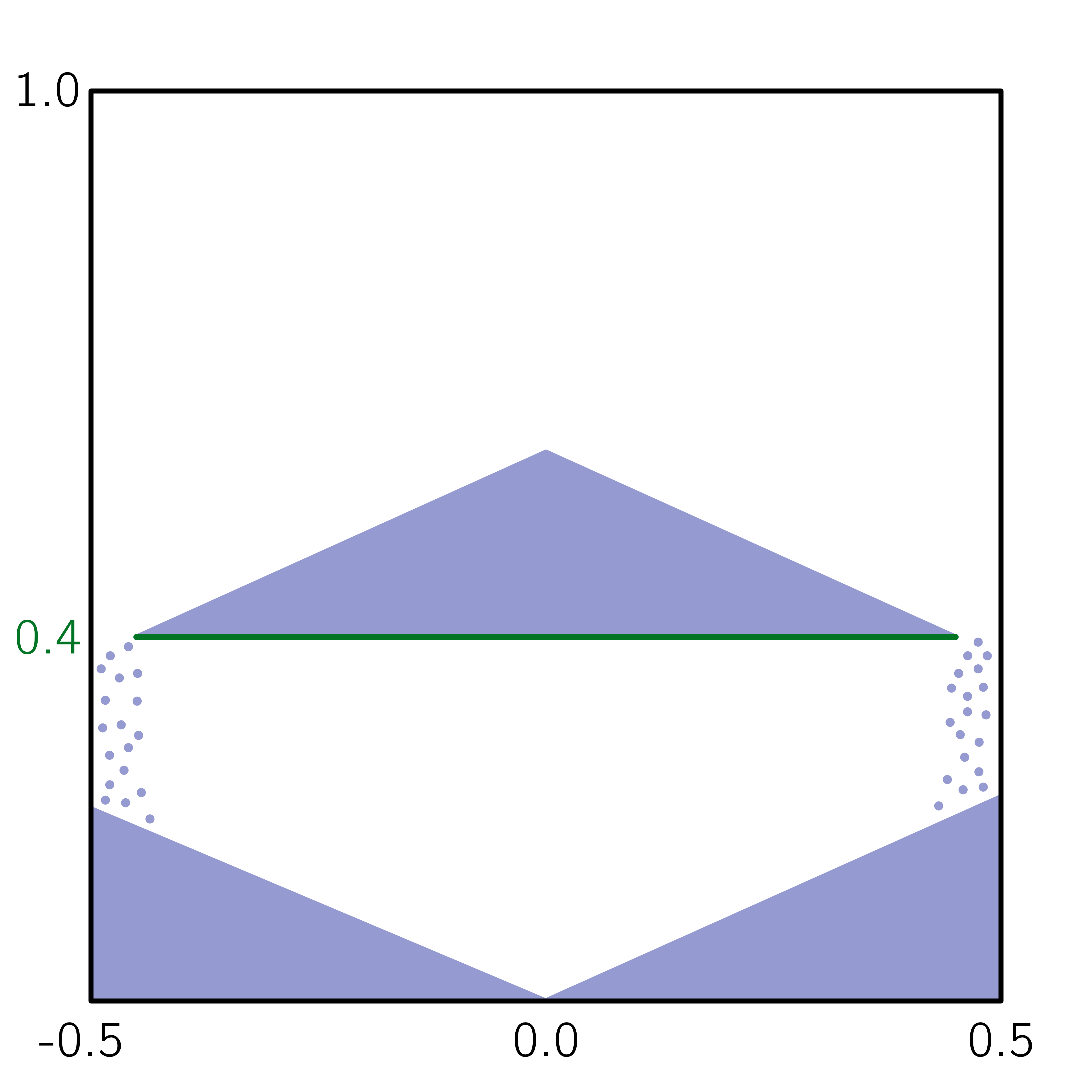

The adaptive sparse contacts method helps the performance of the simulation mostly when there are large areas of motionless particles. As it was showed in the video, those areas are located in the core of the pile at the top and at the corners of settled particles below the plate. This explains why the ASC gives a limited performance gain at the start of the simulation (only from the core of the pile) and an increasing gain through the simulation (accumulation of motionless particles at the bottom part). Given that both methods help the computation performance at different times, their combination gives the best performance as observed. The angles of repose are calculated from the data extracted from the VTU output files. The 2 angles of repose are calculated from the pile of particles on the plate for comparison with the literature, and from the piles formed by the discharge for curiosity. The configuration of the case gives a symmetrical formation of the piles, meaning that there are 2 angles of repose to calculate for the pile at the top of the plate and for the 2 piles at the bottom. The angles of repose are calculated by linear regressions from the highest particle positions in y-axis from \(-0.35 \ \text{m}\) to \(-0.15 \ \text{m}\) for the left angles and from \(0.15 \ \text{m}\) to \(0.35 \ \text{m}\) for the right angles along the x-axis. The following figure shows the areas where the angles are calculated. The areas where the angle of repose is calculated for the left (blue) and right (red) sides of the piles. In order to show how the results may fluctuate, we show the angle obtained from the particle positions from the left and the right sides of the top pile (left plot) and of the 2 piles at bottom (right plot) as solid lines.

The given angles of repose are the linear regressions from the positions with absolute x coordinates. The angles of repose calculated from the simulation data. The solid lines are the angles computed from the highest particles on both side, while the shaded areas represent the angles for the left and the right.# According to Zhou et al. [1], the angle of repose for this type of configuration is calculated with the following empirical formula: where \(\mu_{\text{f,pp}}\) and \(\mu_{\text{f,pw}}\) are the friction coefficients of the particle-particle and particle-wall interactions, respectively, \(\mu_{\text{r,pp}}\) and \(\mu_{\text{r,pw}}\) are the rolling friction coefficients, and \(d_p\) is the particle diameter. The meaning of the rolling friction coefficient \(\mu_{\text{r}}^{\text{eqt}}\) by the authors [1] is different than \(\mu_{\text{r}}^{\text{Lethe}}\) found in Lethe. They express the coefficient as a length in the rolling friction model. However, they also use the constant torque, therefore the rolling friction coefficient in Lethe has to be multiplied by the effective radius of the particle for the results comparison: The theoretical angle of repose is \(19.7^\text{o}\). We did not compute the mean of the angles of repose in order to compare the results with the literature since, even after \(15 \ \text{s}\) of simulation, some particles are still falling from the top. The angles are still not converging to a value. We can however state that the angles are close to the literature. Here we can see that the top angles from all simulations are in a range of around \(\pm 1.5^\text{o}\) from the baseline case, which we consider as a good agreement. We can clearly see a trend in the bottom angles using the ASC. The angles of repose are about \(2^\text{o}\) below the baseline and load balancing cases. It seems to be caused by the accumulation of particles at the bottom of the piles.Post-Processing Code#

pyvista_utilities.py and log_utilities.py.

Extraction, post-processing and plotting are automated in the script plate-discharge_post-processing.py:Performance Analysis#

Angle of Repose#