3D Static Mixer Using RBF Sharp Immersed Boundary#

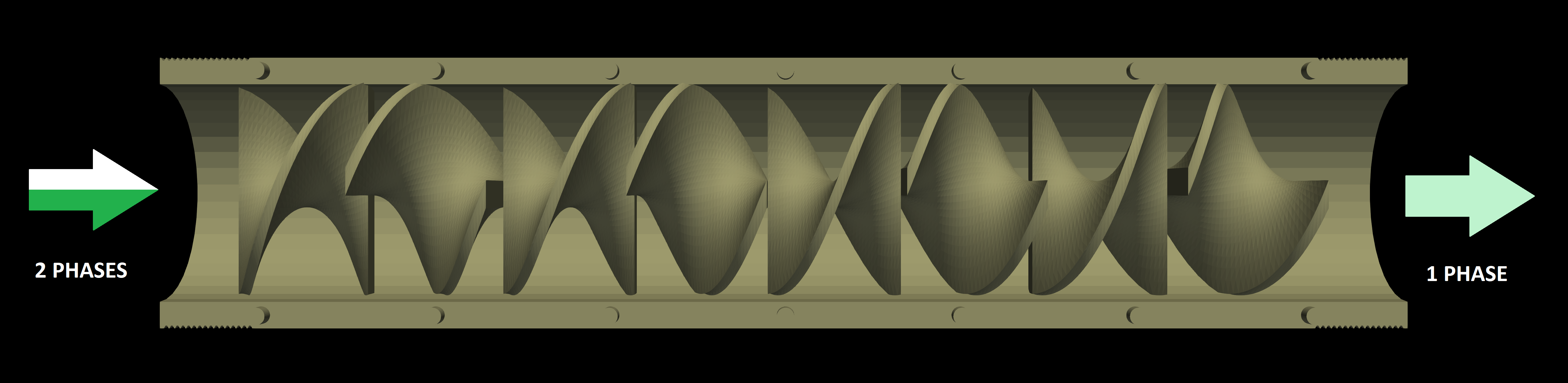

The usage of static mixers is common for the blending of multi-component products in polymerization, as well as water treatment and chemical processing. They involve no moving part, but obtain mixing effects by converting the pressure gradient to radial mixing and flow division as the flow progresses through obstacles. Their advantages include low maintenance, no external energy input, continuous operation, compact design (pipe insertion), and easy installation.

As opposed to stirred tanks, it is not possible to modulate rotation speed or change the impeller. Hence, the design of these systems must be approached with precision due to these limitations. Factors such as the desired level of mixing and the properties of the fluids involved must be carefully considered.

Features#

Solvers:

lethe-fluid-sharpTransient problem

Complex static solid defined by a surface grid (STL) and modeled with the Radial Basis Function (RBF) sharp immersed boundary method

Files Used in this Example#

All files mentioned below are located in the example’s folder (/examples/sharp-immersed-boundary/3d-rbf-static-mixer/).

RBF preparation files:

Parameter file:

rbf_generation/RBF.param;Surface grid file:

rbf_generation/helix.stl. This surface grid was taken from Thingiverse [1] under CC BY 4.0.

Lethe’s fluid simulation files:

Composite geometry file:

lethe_sharp_simulation/mixer_long.composite;Parameter file:

lethe_sharp_simulation/flow_in_long_mixer.prm;RBF geometry file:

lethe_sharp_simulation/RBF_helix.output. The extension is.outputbecause it was named from a bitpit perspective.

Description of the Case#

In this example, we showcase the RBF type of objects used in Lethe’s resolved immersed-boundary Navier-Stokes solver.

Preparation of the Solid#

Generation of the RBF file from the STL#

bitpit is an open-source modular library for scientific computing. The current section presents an example using its RBF capabilities to train RBF-networks that approximate the geometry from surface grid objects (.stl).

Tip

In order to install bitpit, you need to have the github version of PETSc, which itself requires BLAS/LAPACK and LibXML2. In order, BLAS/LAPACK and LibXML2 must be installed, then PETSc, then bitpit.

For the dependencies installation, you can use:

For the PETSc installation, you must first create a directory for the installation, then clone the project and configure it. Here are a few lines to help set it up:

For the bitpit installation, you must first create a directory for the installation, then clone the project and build it (ideally in a separate directory). The dependencies’ paths must be specified. Here are a few lines to help compile bitpit with 6 processes:

After compiling the library, we can use an executable /examples/RBF_example_00001, along with a parameter file and the helix.stl in the rbf_generation directory.

The parameter file (RBF.param) contains:

nb_subdivision nb_adaptions radius_ratio base_function mesh_range

16 4 3 1 0.1

The number of subdivisions in each of the three spatial dimensions:

16;The number of adaption cycles. Using

4adaptation cycles over a initial number of16subdivisions results in a level of detail equivalent to a number of256subdivisions;The radius ratio means that each node sees up to

3neighbors in each direction, which results in a smooth approximation.The base function of

1means that the basis function is of Wendland type. This is the best function to represent geometries, from our experience.The mesh range of

0.1means that there is at least 10% of margin on each side of the object, so the collection of RBF nodes are encompassing the whole object.

Assuming that the RBF_example_00001 executable is within your $PATH or copied to /rbf_generation/ directory, we can launch the RBF generation from /rbf_generation/ using the command line:

After about 40 minutes, this executable will output RBF_helix.output, which is the encoding of the shape, and RBF_helix.vtu, which can be used to see the resulting approximation.

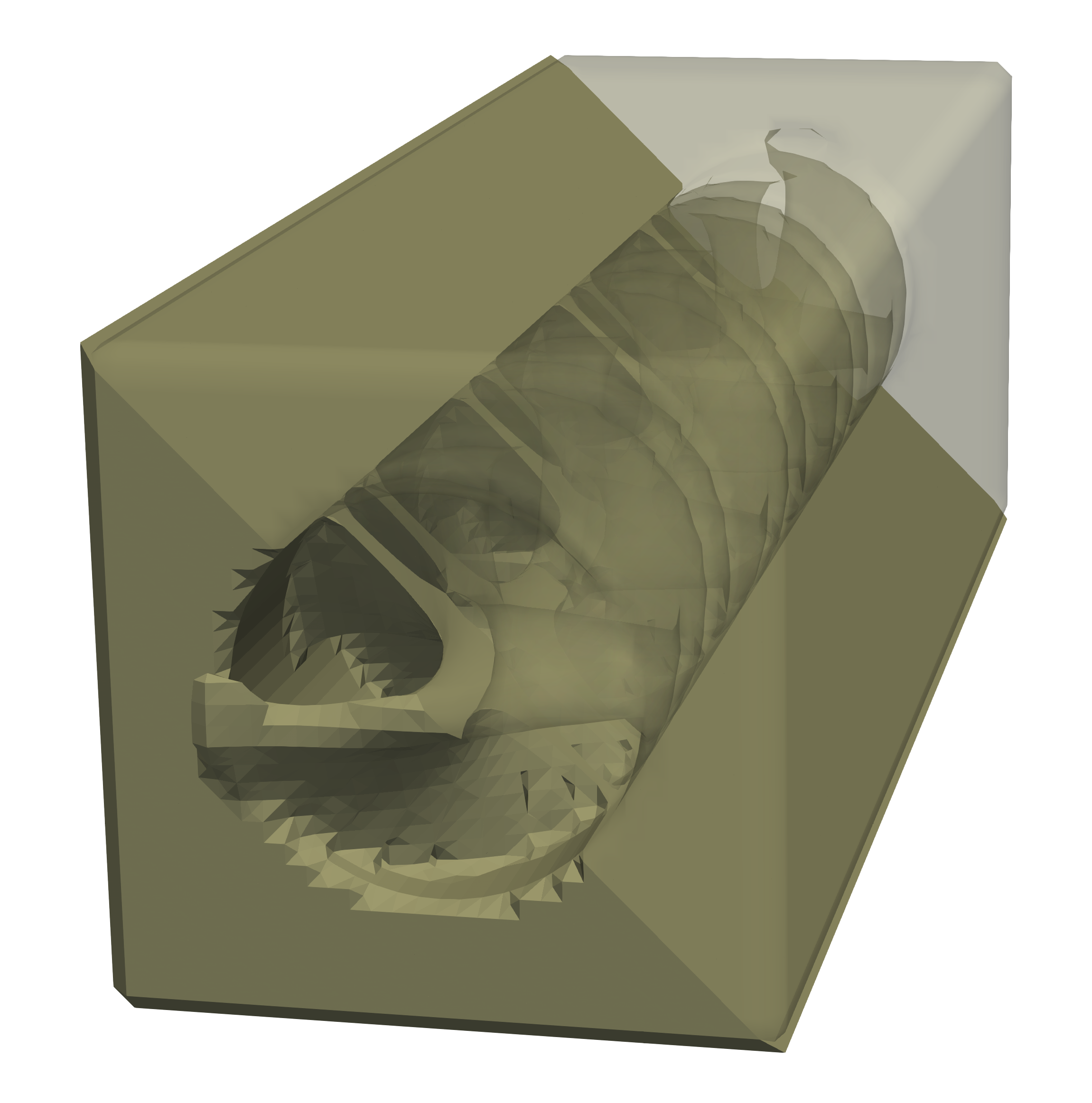

Creation of the Composite Shape File#

The complete geometry through which the fluid flows contains the helix static mixer as well as the casing around it. We use composite shapes to build the complex geometry; this type of shape is introduced in this example: Simple Plane Model From Composite. The main particularities of the current composite shape are:

The translation parameter for the

rbfshape is-76.201:-20.0098:+15.6051. It is selected to ensure that the center of the static mixer is located at the origin. The coordinates are taken fromrbf_generation/bitpit.log.The

hyper rectangleis long enough to cover the length of the helix, and just large enough to fit in the background grid.The

cylinderhole is set to have a very high length to ensure that the difference operation applies properly over the whole domain.Operation

15forms the casing, and operation16joins the casing and the helix. The final operation is the one considered as definitive.

shapes

0; rbf ; RBF_helix.output; -76.201:-20.0098:+15.6051; 0:+1.57079632679:0

1; hyper rectangle ; 75:25:25; 0:0:0; 0:0:0

2; cylinder ; 15:10000; 0:0:0; 0:+1.57079632679:0

operations

15; difference ; 2:1

16; union ; 0:15

Parameter File#

Simulation Control#

Although we are interested in the steady-state solution of the flow, we use bdf1 time integration. The required time to reach steady state in our case is low, but solving it with a small time step enables the non-linear solver to converge as complex flow patterns are difficult to capture otherwise.

subsection simulation control

set method = bdf1

set time end = 40e-4

set time step = 1e-4

set output path = ./output/

set output name = output

end

Physical Properties#

We assume that the fluid is water, and that the length of the static mixer is in the order of \(150 \, \text{cm}\). Hence, the length units are centimeters and the time units are seconds. The kinematic viscosity of water is \(0.01 \, \text{cm²}/\text{s}\).

subsection physical properties

subsection fluid 0

set kinematic viscosity = 0.01

end

end

Stabilization#

We rescale the pressure for solving the Navier-Stokes equations by using a pressure scaling factor = 1e2. Because the flow is heavily restricted by the geometry, unless rescaling is applied, the pressure range and its oscillations are way higher than the velocity magnitude, which negatively affects the convergence of the linear solver. More information on this parameter is available at doc:../../../parameters/cfd/stabilization.

subsection stabilization

set pressure scaling factor = 1e2

end

Mesh and Mesh Adaptation#

The mesh is a simple hyper rectangle, large enough to encompass the mixer with its casing and long enough to establish the flow profile upstream and downstream.

subsection mesh

set type = dealii

set grid type = subdivided_hyper_rectangle

set grid arguments = 6,1,1: -150,-25,-25: 150,25,25: true

set initial refinement = 3

end

Mesh adaptation type is set to adaptive, to allow adaptive refinement at the solid surface using the kelly error estimator. This is necessary for simulations of this type because of the prohibitive mesh size required when only uniform refinement is used. Setting max refinement level = 5 allows for two levels of adaptive refinement from the uniform initial refinement = 3 defined in the mesh section. The frequency = 0 ensures that no refinement occurs between time steps, as it is not necessary here. The initial refinement steps = 0 to highlight that no initial refinement is requested here; the initial refinements are requested from subsection particles because they are base on the solid geometry.

subsection mesh adaptation

set type = adaptive

set error estimator = kelly

set fraction type = number

set max number elements = 2000000

set max refinement level = 5

set min refinement level = 0

set frequency = 0

set initial refinement steps = 0

end

Definition of the Shape#

This section defines each parameter for the particles and has certain requirements:

subsection particles

set assemble Navier-Stokes inside particles = false

set number of particles = 1

subsection extrapolation function

set length ratio = 4

set stencil order = 1

end

subsection local mesh refinement

set initial refinement = 4

set refine mesh inside radius factor = 1

set refine mesh outside radius factor = 1

set refinement zone extrapolation = false

end

subsection particle info 0

set type = composite

set shape arguments = mixer_long.composite

end

end

In

subsection extrapolation function,length ratiodefines the length used to apply the immersed boundaries through interpolation. We choose4as a compromise between a low value, which is better for the linear solver, and a high value, which is better for mass conservation. Mass conservation can also be improved using a finer grid.In

subsection local mesh refinement,refine mesh inside radius factorandrefine mesh outside radius factorare both set to1, which activates minimal crown refinement mode.In

subsection particle info 0,type = compositeandshape arguments = mixer_long.compositedefine the shape itself. This requires that theRBF_helix.outputis located in the same directory as the parameter file.

Boundary Conditions#

A condition is assigned to each boundary:

The inlet is set to a Dirichlet boundary condition with unit velocity in the x direction.

The outlet is defined as such, and is the weakly imposed condition required when using

lethe-fluid-sharp.The remaining boundaries are set as

noslipto emulate the flow in a channel.

subsection boundary conditions

set number = 6

subsection bc 0

set id = 0

set type = function

subsection u

set Function expression = 1

end

end

subsection bc 1

set id = 1

set type = outlet

end

subsection bc 2

set id = 2

set type = noslip

end

subsection bc 3

set id = 3

set type = noslip

end

subsection bc 4

set id = 4

set type = noslip

end

subsection bc 5

set id = 5

set type = noslip

end

end

Post-Processing#

Pressure drop and flow rate post-processing are enabled to track when steady state is reached and to ensure that mass is preserved. Too high variations between inlet and outlet flow rates are linked to increased error on the pressure drop predictions.

subsection post-processing

set verbosity = verbose

set calculate pressure drop = true

set calculate flow rate = true

set inlet boundary id = 0

set outlet boundary id = 1

end

Running the Simulation#

The simulation can be launched on multiple cores using mpirun and the lethe-fluid-sharp executable. Using 6 CPU cores (for an approximate runtime of 50 minutes), the simulation can be launched with:

Results#

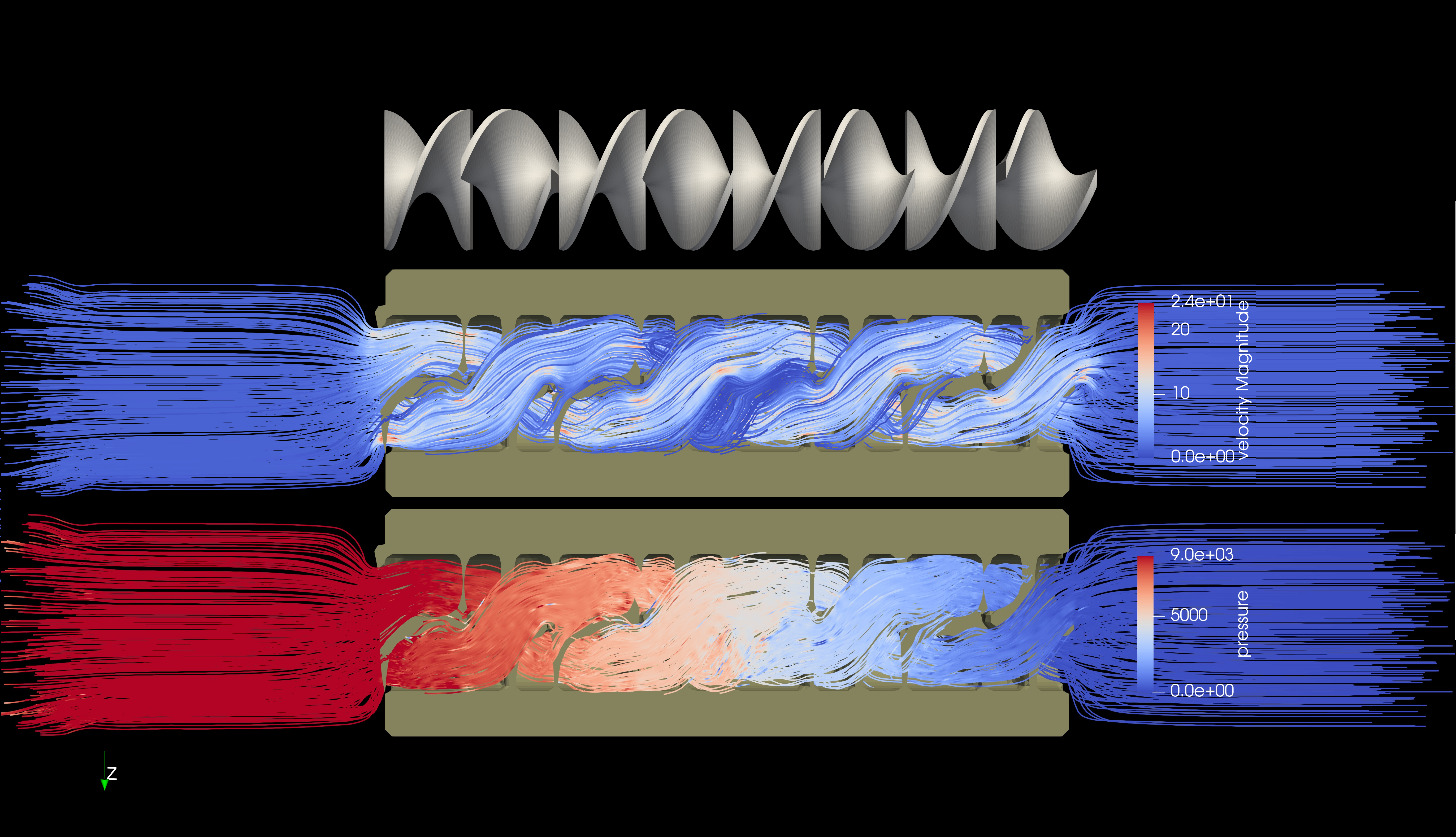

After the simulation has run, streamlines can be used to visualize the pressure and velocity fields through the static mixer, as well as show the mixing effects that can be obtained.

The mass conservation and pressure drop can both be monitored by plotting their values in time, extracted from /output/flow_rate.dat and /output/pressure_drop.dat. The Python script postprocess_flow_and_pressure.py generates the following plot:

As the plot shows, the mass conservation is constant after only a few time steps; it depends mostly on the length ratio, residual and grid refinement. The pressure drop, on the other hand, decreases steadily. We stopped the simulation after 40 time steps because the decrease is then low enough, but increasing the total duration would be interesting to get a better idea of the steady-state pressure drop.