Laser Heating#

This example simulates a three-dimensional solid block heated with a laser beam which follows a complex path. This mimics an additive manufacturing process.

Features#

Solver:

lethe-fluidLaser heat source

Convection-radiation heat transfer boundary condition

Unsteady problem handled by an adaptive BDF2 time-stepping scheme

Time-dependent laser path

Mesh adaptation using temperature

Files Used in This Example#

Parameter file:

examples/multiphysics/laser-heating/laser-heating.prm

Description of the Case#

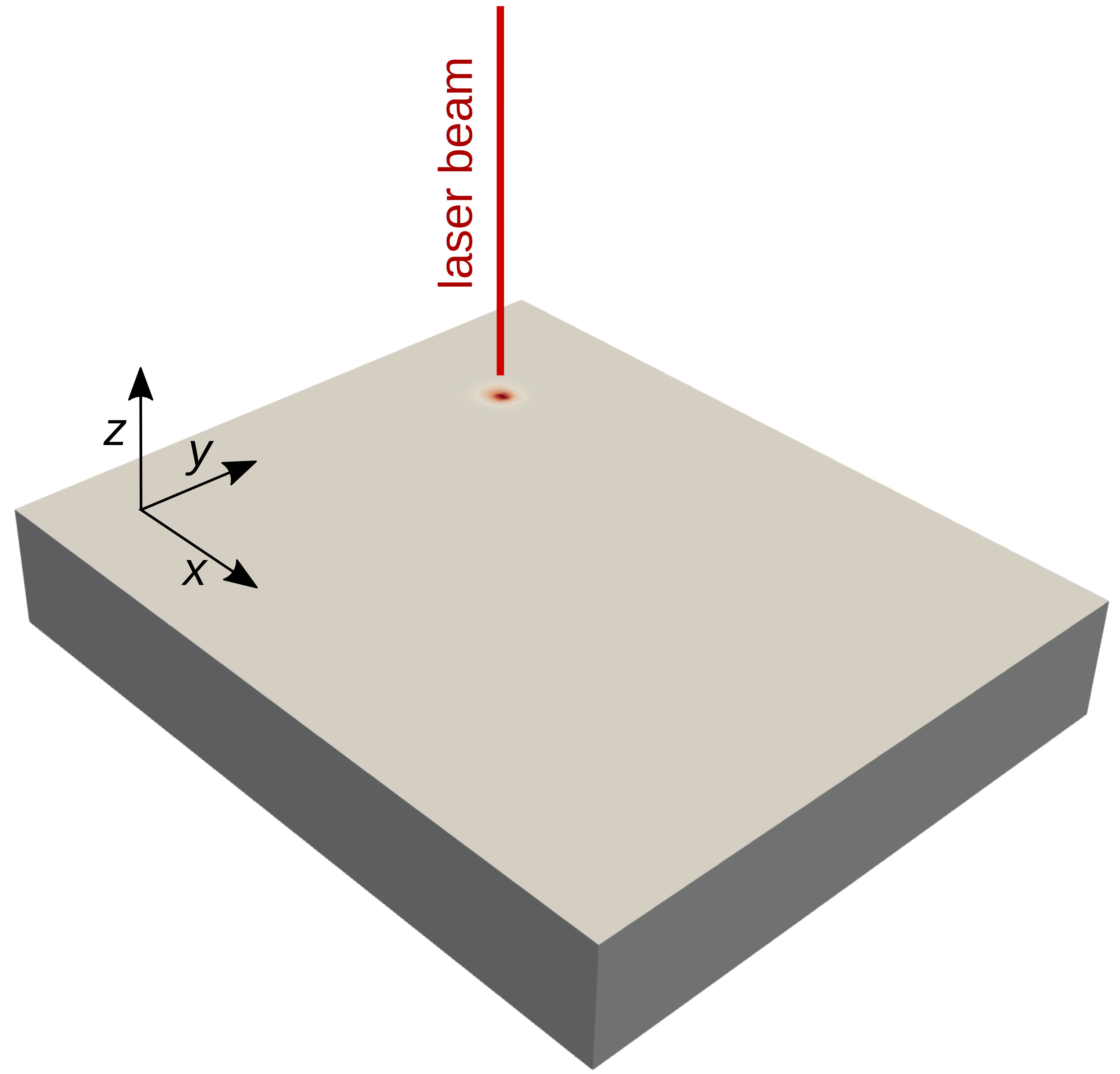

A laser beam heats a three-dimensional solid block. The laser beam is emitted perpendicular to the top surface of the block in the negative z direction. The following schematic describes the geometry and dimensions of block and laser beam:

The laser path changes with time. The laser beam radius and penetration depth are both set to \(0.00005\) m. Because of this small radius and penetration depth, we use adaptive mesh refinement based on the temperature. Thermal boundary conditions are convection-radiation-flux with a convective heat transfer coefficient of 5 and an emissivity of 0.4. The corresponding parameter file is:

laser-heating.prm.

Parameter File#

Time integration is handled by a 2nd order backward differentiation scheme (bdf2) (for a better temporal accuracy), for a \(0.003\) seconds simulation time with a constant time step of \(5.0 \times 10^{-5}\) seconds.

Simulation Control#

subsection simulation control

set method = bdf2

set time end = 0.003

set time step = 0.00005

set output name = laser-heating

set output frequency = 1

set output path = ./output/

set subdivision = 1

end

Boundary Conditions#

All the boundary conditions are noslip, and the heat transfer boundary conditions are convection-radiation-flux.

subsection boundary conditions

set number = 1

subsection bc 0

set type = noslip

end

end

subsection boundary conditions heat transfer

set number = 1

subsection bc 0

set type = convection-radiation-flux

subsection h

set Function expression = 5

end

subsection Tinf

set Function expression = 20

end

subsection emissivity

set Function expression = 0.4

end

end

end

Multiphysics#

The multiphysics subsection enables to turn on (true) and off (false) the physics of interest. Here only heat transfer is enabled.

subsection multiphysics

set heat transfer = true

end

Laser Parameters#

In the laser parameters section, the parameters of the laser model are defined. The exponential decaying model [1] is used to simulate the laser heat source. In the exponential decaying model, the laser heat flux is calculated using the following equation:

where \(\eta\), \(\alpha\), \(P\), \(R\), \(\mu\), \(r\) and \(z\) denote concentration factor, absorptivity, laser power, beam radius, penetration depth, radial distance from the laser focal point, and axial distance from the laser focal point, respectively. These parameters are explained in more detail in the laser parameters.

Note

The scanning path of the laser is defined using a Function expression in the path subsection. Here the laser path is a function of time, and changes its direction twice during laser operation.

subsection laser parameters

set enable = true

set type = exponential_decay

set concentration factor = 50

set power = 3

set absorptivity = 0.6

set penetration depth = 0.00005

set beam radius = 0.00005

set start time = 0

set end time = 0.003

set beam orientation = z-

subsection path

set Function expression = if(t<0.001, 0.5 * t, if(t<0.002, 0.0005, if(t<0.003 , 0.0005-0.5 * (t-0.002), -1))); if(t<0.001, 0.00025, if(t < 0.002, 0.00025 - 0.5 * (t-0.001) , if(t < 0.003 , -0.00025, -1))) ; 0.0003

end

end

Mesh Adaptation#

In the mesh adaptation subsection, we choose a mesh refinement based on the variable temperature. Mesh adaptation is explained in more detail in mesh adaptation control

subsection mesh adaptation

set type = kelly

set variable = temperature

set fraction type = fraction

set max refinement level = 4

set min refinement level = 0

set frequency = 1

set fraction refinement = 0.5

set fraction coarsening = 0.2

end

Running the Simulation#

Call the lethe-fluid by invoking:

to run the simulation using eight CPU cores. Feel free to use more.

Warning

Make sure to compile lethe in Release mode and run in parallel using mpirun. This simulation takes \(\approx\) 5 minutes on 8 processes.

Results#

The following animation shows the temperature distribution in the simulations domain, as well the laser path.

Possibility for Extension#

This example can be extended to implement phase change (melting the solid block by laser and solidifying again after cooling).